Milacron delivers 12,501st injection machine from Ahmedabad, India pla - 2k inje

Author:gly Date: 2024-09-30

I take care of a cemetery in central Maine, and seeing the condition of a lot of these stones are terrible. My thought of connecting with a manufacturer on making replacement monuments at reasonable prices for municipalities’ and for people that could afford a monument for a loved. I believe there is a market for such a thing. Thank you for your time.

Founded in 2016, Boston-based Fortify is hoping to use new materials and process capabilities to transform in industrial manufacturing of RF modules for satellites and electronic devices. This is done through their FLUX 3D printers, which use Fortify’s Digital Composite Manufacturing (DCM) process. In this technology, photopolymers are used as well as Functional Additives (particles and reinforcing fibers), which are suspended and aligned in a resin matrix during printing. Upon curing, it is possible to have parts with a wide range of material properties at a much higher speed than other composite 3D printing processes.

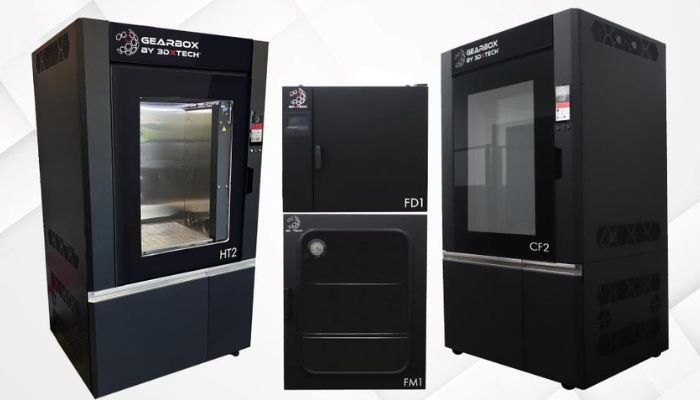

Another American composite 3D printing solutions provider to include is 3DXTECH. Based in Grand Rapids, Michigan, the company is best known for its material solutions including of course carbon fiber reinforced materials, claiming to have the broadest portfolio on the market. But they also have two printers, including one designed specifically for carbon fiber and glass fiber 3D printing, the Gearbox CF2. This printer boasts a number of properties to make it ideal for composite materials that have been reinforced with carbon fiber, including an actively heated chamber that can reach up to 135ºC. It also boosts features like print settings for popular 3DXTECH materials, as well as a hardened system for abrasive materials like composites.

The U.S. additive manufacturing market continues to be the biggest in the world, with the largest number of 3D printer manufacturers, material developers, startups and even 3D printing service providers. But considering its size, it can be hard to know who exactly the players are, which is why we have previously told you about the American metal AM solution providers and manufacturers of FDM printers under $5000. But polymers and metals are just part of the sector. Another realm where we have seen growth in the USA is in composite 3D printing. But who exactly are these players? Where are they based in the country? We take a closer look at this latest listing in this series on the American manufacturers of composite 3D printers.

A research project is exploring new avenues for AI-assisted automated optical quality assurance during the injection molding process.

The process can be burdensome, as the samples are removed, transported, and tested manually, tying up resources. Moreover, the quality of the data depends on the skills and expertise of the personnel performing the inspections. Critical parts may have narrower tolerances and require more frequent spot checks, increasing the potential for human error. Automated, reproducible random sample testing can optimize the process.

The research project is also investigating possible ways to automate data matching and the adaptation of neural networks. Manufacturers not only gain the benefit of improved data quality from optical inspections, they can also design their entire process to be as rigorous and error-free as possible, even in complex production environments where a variety of different parts need to be tested.

3Dnatives is the largest international online media platform on 3D printing and its applications. With its in-depth analysis of the market, 3Dnatives gets over 1 million unique visitors per month and is currently available in English, French, Spanish, German, Italian. 3Dnatives works with key Additive Manufacturing market players and offers a variety of services such as a 3D printing price comparison engine, B2B consulting and B2B brand content, event management and much more!

Based in Washington state, Electroimpact puts itself forward a world leader in design and manufacturing of aerospace tooling and automation. As part of that, they have turned to additive manufacturing, developing their own advanced FFF 3D printing process named the unified Scalable Composite Robotic Additive Manufacturing (SCRAM) system. A 6-axis continuous fiber-reinforced 3D printer allows for the tool-less creation of aerospace-grade integrated composite structures according to their manufacturer. This is what Electroimpact calls “True 3D” printing (rather than what they say is more like 2.5 printing from other processes), since the layers are not constrained to a stack of planes, allowing for complex geometries such as variable density cores and other internal structures. The solution is also compatible with PAEK materials, Nylons and water-soluble thermoplastics along with composites of carbon fiber, glass fiber and boron fiber.

It perhaps will come as no surprise to see 3D Systems on this list. As one of the oldest and most well-established 3D printer manufacturers in the world, 3D Systems has a much wider range of printers available than most others on the market. This includes, of course, solutions for composite 3D printing. We can point especially to the ProJet MJP 5600 was designed specifically for 3D printing large-format, multi-material composite parts in a single build. This machine uses 3D System’s MultiJet printing process, a type of inkjet printing process similar to material jetting, which involves the jetting of photocurable plastic resin or casting wax materials layer by layer. Specifically, within the ProJet MJP 5600 3D printer, it is possible to combine flexible and rigid photopolymers to achieve superior mechanical properties and custom performance characteristics, notably with 3D System’s Visijet multi-material composites. That being said, composite 3D printing is also possible on other machines, including for SLS 3D printers and the Titan line of FDM printers.

Additional injection molding machines producing different parts can be integrated into this setup and incorporated into the material flow with the use of autonomous vehicles. In other words, the concept allows for automation of quality control in complex production environments as long as the test cell is equipped with the appropriate inspection programs: The inspection system recognizes the different parts and triggers the relevant test program.

Following inspection, the autonomous vehicle transports the tested parts to the warehouse and the test cell sends the analyzed data to higher-level QA or MES systems. Experts can then compare the quality data with the quality forecasts previously generated by ComoNeo PREDICT. If variances occur, the AI models are retrained using new test data.

Dr.-Ing. Oliver Schnerr is head of sales, Integrated Solutions Automation Solutions / Vision Systems / Fastening Technology at Kistler.

Another to put on the list of American composite 3D printer manufacturers is Impossible Objects. The creators of its own patented composite-based additive manufacturing technology (CBAM), Impossible Objects is dedicated primarily to the creation of composite parts as they seek to “produce the world’s strongest additively manufactured composite parts at injection molding speeds.” Indeed, with the CBAM 25 and CBAM-2, the company says it is possible to make industrial-grade composites parts at a rate 1600% faster than other carbon fiber 3D printing systems. Their systems boast as well a real time detection and avoidance system which integrates automatic printing monitoring and correction and is compatible with even advance polymers such as PEEK.

Another well-established American company that also has turned to additive manufacturing is Ingersoll Machine tools, which was purchased by the Camozzi Group in 2003. Currently, for composite 3D printing, the company offers the MasterPrint® 3X, a large-format, industrial, hybrid 3D printer which can simulate, 3D printer and mill extra-large composite parts in a single piece. The hybrid machine can operate with multiple modules including 3D printing, milling, fiber placement, tape laying, inspection and trimming, making it perfect for sectors such as aerospace, naval or even automotive. The company also offers other solutions including the MasterPrint® Continous Filament for continuous fiber-reinforced polymers, the MasterPrint® 5X, the MasterPrint® Linear and the MasterPrint® Robotic.

SPE Middle East Office N. ESO:14, Desk 34 Sheikh Rashid Tower, Seventh Floor Dubai World Trade Center P.O. Box 9204 Dubai, UAE

Manufacturers typically rely on statistical process control (SPC) to verify quality. The frequency and scope of sample testing is defined, enabling users to monitor the production process according to predefined quality parameters.

The objective is to achieve consistently smooth and efficient part handling throughout the entire test process. Integrated safety concepts monitor the systematic progression of the individual steps in the process — as well as the “handshakes” — to guarantee process reliability while preventing data loss. The automatic system then sends the collected data via an OPC UA interface to the operator's higher-level quality assurance system and to relevant databases for analysis.

Probably one of the most well-known among the list of American manufacturers of composite 3D printers is Markforged. Though it recently also moved into metal binder jetting, Markforged is primarily known for its industrial and desktop composite 3D printing solutions, as well as its wide range of available materials. All eight printers from the company are compatible with continuous fiber 3D printing, including the latest launch, the FX10™. Adding to that, Markforged also gives users access to “The Digital Forge,” a platform designed specifically for additive manufacturing and allowing software, printers and materials to be unified and easily controlled. Showing even more clearly the company’s commitment to industrial additive manufacturing.

What do you think of this list of the American manufacturers of composite 3D printers? Did we forget anyone? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

84 countries and 60k+ stakeholders strong, SPE unites plastics professionals worldwide – helping them succeed and strengthening their skills through networking, events, training, and knowledge sharing. For more information, visit www.4spe.org.

Quality control is an essential aspect of the production process, especially when it involves parts used in automotive and medical technology applications. The entire quality control process must be designed to ensure maximum precision and reproducibility, and typically requires reams of documentation. All of this is labor-intensive and time-consuming, and is reliant on expert personnel. Automation coupled with artificial intelligence (AI) may offer an alternative.

Autonomous vehicles transport parts to the test cell and storage area. Image courtesy of OST – Ostschweizer Fachhochschule.

Compare Desktop 3D Printers Compare Professional 3D Printers Compare 3D Scanners 3D Printing Directory Choose a 3D printer 3D Printing Directory Event Board Job Board Newsletter Advertising

The molded parts are serialized using individual QR codes and sorted onto trays. While production is still in progress, Kistler’s ComoNeo system monitors cavity pressures via pressure sensors. With support from appropriately trained AI, ComoNeoPREDICT software generates quality predictions for the individual parts. Driverless transport vehicles convey parts selected for spot checks to the optical test cell. This is the first time autonomous transportation has been used in this context. The parts then pass through the predefined inspection program and are checked for dimensional stability and surface defects as well as injection molding anomalies, such as black specks or moisture splay. Issues specific to plastics processing such as shrinkage due to cooling and crystallization are also taken into account.

Another old and well-established manufacturer on this list, is Stratasys. The Israeli-American company, like 3D Systems, has an extremely wide range of solutions using many different 3D technologies. This includes of course composite 3D printing, through the F123CR Series, which allows for the creation of carbon-fiber and industrial-grade parts. Made up of the F190CR and F270CR systems, these FDM 3D printers are compatible with a wide range of materials, including ABS-CF10 and Nylon-CF10.

Switzerland-based Kistler, a developer of measurement systems and sensors, is collaborating with the Eastern Switzerland University of Applied Sciences (OST) in researching advanced quality-control technologies. In particular, Kistler is involved in a project with the university’s IWK Institute for Materials Technology and Plastics that fully automates the inspection of injection molded parts while harnessing the power of AI to hone quality predictions while injection molding.

The research project with the IWK Institute for Materials Technology and Plastics Processing is focused on injection molding of a medical part. The objective is to develop a system that provides medtech manufacturers with comprehensive automated random sample inspection, generating accurate AI-based quality predictions while injection molding is still in progress.

When starting to design an inspection concept of this sort, the focus initially is on the requirements for the part being tested. The project team collaborates with manufacturers to develop the required quality-relevant test parameters, mostly related to surface defects and dimensional accuracy. They also identity the appropriate test methods. Kistler-developed sensors make it possible to integrate mechanical pressure and force and torque tests. Experts from the company’s competence center then design the test cell accordingly. In addition to determining the number and positioning of camera stations with lighting elements, the key factor at this stage is outlining the inspection path for the part.

The next one on our list of American manufacturers making composite 3D printers is perhaps best known for its work in the aerospace sector, hence its name, Orbital Composites. But this Campbell, California manufacturer does not just offer services, it also is known for its large-scale, composite 3D printing “factories,” under the motto to “leverage the power of robots like never before.” Offering the Orbital e-, Orbital S-, Orbital F- and AMCM systems, the company is developed to multi-axis, large-scale manufacturing with including for making wind blades, satellite parts, rockets and more.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly