Is Your Record Really Made of Vinyl? - polystyrene injection molding

Author:gly Date: 2024-09-30

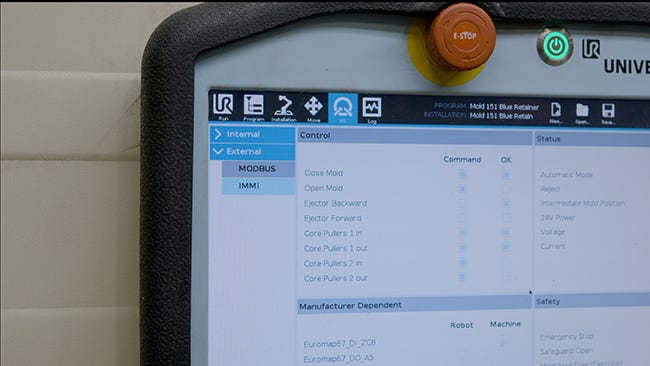

Universal Robots (UR) is giving injection molders an easy-to-use interface that seamlessly connects its cobots to injection molding machines (IMMs) — a capability made possible thanks to the standardization of IMMs through the Euromap 67 standard.

Volk has spent more than 30 years in the additive manufacturing industry before deciding to launching AAI in 2022. At that time, he began to notice a surging adoption level of plastic 3D printing among businesses.

AAI's customer base is about 75% consumer, but the professional client side is growing. “We have a large segment of customers who come to us with their engineered prototypes. They’re entrepreneurs making devices and trying to get them to market,” says Volk.

UR cobots are light enough to be wheeled from machine to machine, as required, Buse added, so users can “treat the cobot more as an operator.” And because UR cobots can be positioned flexibly simply by specifying an orientation through the control screen, users can bolt them to the platen of a press, on the side, or “in any orientation you can think of.”

“More companies in more industries are adopting additive manufacturing for both prototyping and final production, especially as the material options expand and machines become even more reliable,” says Kring, “Craftcloud is in a great position to expand our offerings to meet this demand.”

Cobots offer injection molders unique benefits over traditional gantry robots, Buse continued. For instance, manufacturers with more compact production floors and low ceilings can’t always accommodate tall gantry robots.

“Because 3D printing is so versatile, covering plastics and metals, it has not only cornered the prototype market but is becoming more popular for bridge manufacturing and medium-volume end-use parts,” says Mikkel Kring, Craftcloud’s chief product officer.

When connected, the UR cobot is integrated with the IMM’s safety features, including emergency stop circuits and safety doors. As the injection molding machine is running, it tells the cobot exactly what’s going on in real time so the cobot can perform its functions safely at just the right time.

NASCAR driver Ryan Blaney, right, was awarded the Goodyear gold car trophy in 2023 for winning the ... [+] NASCAR Cup Series championship. Parts of the detailed replica car are 3D printed at Advanced Additive Innovations then metal plated.

Geoff Giordano is a tech journalist with more than 30 years’ experience in all facets of publishing. He has reported extensively on the gamut of plastics manufacturing technologies and issues, including 3D printing materials and methods; injection, blow, micro and rotomolding; additives, colorants and nanomodifiers; blown and cast films; packaging; thermoforming; tooling; ancillary equipment; and the circular economy. Contact him at [email protected].

Integrating UR cobots with IMMs is as simple as installing the IMMI plug on the cobot’s controller and running a cable between the injection molder and the cobot, Buse explained. The Euromap 67 IO communication protocol means the IMMI runs on all brands of contemporary IMMs; some older machines can be retrofitted.

“Mass customization just can't be done any other way efficiently and it’s going to be the most important thing for us in the coming years,” Klassen says. “There's no point in going after the injection molding market or the CMC market for certain things. They've really developed that process to reduce material costs. We need to focus on what we do best and that's the customization side.”

The company’s network of providers offers more than 120 materials and produces parts with six 3D printing technologies, including fused deposition modeling (FDM), which uses plastic filament ideal for quick prototypes, and metal laser powder bed fusion (LPBF), used to print metal components.

“Some companies change the product design at every order, which they couldn’t do with traditional manufacturing,” says Klassen. “This flexibility makes companies more nimble and competitive in their markets.”

Mikkel Kring, chief product officer at Craftcloud 3D printing marketplace, credits his customer ... [+] service team with helping businesses better understand 3D printing.

Not only have large 3D printing services like Protolabs Network and Materialise added new facilities to meet demand in the past few months, more 3D printing companies are entering the market, many led by entrepreneurs who turned their interest in 3D printing as a hobby to capitalizing on their expertise as a businesses.

Craftcloud has grown with the professional and industrial adoption of 3D printing since the company launched in 2016 and now caters to more businesses than ever. “We’ve seen substantial adoption of additive manufacturing across a huge swath of industries, particularly automotive, healthcare, and small manufacturing,” says Kring.

One customer, for example, came to JawsTec with an idea to manufacture custom hair clipper guards designed to produce specific hair styles and customized for specific barbers. What started as a prototype customer, became a manufacturing customer that 3D prints dozens of unique designs at a time.

One JawsTec customer that 3D prints air intakes for a sports car manufacturer moved away from injection molding because 3D printing enabled it to stay ahead of the competition. “Every order was changing and they were always improving and revising, putting holes in different places, and using different tolerance requirements. It's been really interesting to see how they've developed their product over the years.”

JawsTec 3D prints nearly 40,000 parts each month, with the largest growth segment lately coming form healthcare, including patient-specific orthotic shoe inserts and braces. These products are digitally designed based on a 3D scan of an individual. Orders sent in to JawsTec by practitioners and medical companies can top 40 per day.

At Protolabs, CEO Rob Bodor attributes part of his company's growth in the last year to the expanded ability to manufacture end-use production parts. “Our large customer base has been used to relying on us for their prototyping and now we can serve them for the entire life cycle of their products, through production and end of life,” he says.

The additive manufacturing services sector (or 3D printing contract manufacturers) grew 20% in 2023, and will grow 22.7% in 2024 to reach $7.5 billion, according to market watchers The Business Research Company, Persistence Market Research, and others. The worldwide 3D printing service bureaus market is expected to grow at a booming CAGR of 22.3% during 2024-2030, says Infinity Business Insights.

“When you need to introduce a robot into that cycle, the robot needs to break into that molding process in order to go into the mold safely, extract the plastic parts, and then get out of there safely to allow the mold to shut again,” Buse explained. “That is what the Euromap 67 plug interface is doing. Users can control the sequence through the cobot’s teach pendant on the screen. The software is already embedded — all you have to do is turn it on when you install the line. When you get the inputs and outputs between both machines, you can start programming.”

Xometry and Protolabs do not report revenue from 3D printing separately from their injection molding or CNC machining work, but Protolabs recently surveyed more than 700 end-users for a pulse check on the use of 3D printing.

Our community is about connecting people through open and thoughtful conversations. We want our readers to share their views and exchange ideas and facts in a safe space.

Craftcloud, a marketplace of 3D printing services where customers upload their digital part files and select from a network of more than 150 3D printing service providers, reported a 31% rise in revenue in 2023, representing its best year yet.

At Idaho-based 3D printing service company JawsTec, the customer base has also shifted from mostly hobbyists in 2018 to today nearly 90% business customers, especially a wide range of entrepreneurs, according to Oscar Klassen, CEO and cofounder. “Companies order prototypes then return for the volume production of the final product.”

The growth in outsourcing 3D printing to specialized service bureaus, mirrors the decline in industrial 3D printer sales as companies put off capital expenditure in the current economic slump.

“If we can move more manufacturing over to additive, there's less competition from overseas suppliers, more localized manufacturing, and a way to sustain domestic manufacturing,” says Klassen.

Because there’s no minimum order number or minimum oder dollar value at JawsTec, start-ups can become manufacturers with virtually no investment, unlike with other manufacturing methods, such as injection molding that require costly molds.

The 3D printing service bureaus market is made up of a broad set of companies ranging from huge worldwide enterprises — many of which also offer traditional manufacturing, such as injection molding and CNC machining — and smaller, specialized firms focused on specific sectors or technologies.

Feedback showed that 70% of business customers printed more parts in 2023 than the year before and the use of 3D printing for end-use parts was up.

And, a cobot allows for “cageless automation” — taking parts out of the dangerous, guarded production environment, then reaching outside that area into an unguarded area like a conveyor belt. Users can also program the cobot to perform secondary operations like degating from the runner or presenting parts to a laser marker.

While UR’s UR10 cobot is the most popular among injection molders, Buse said, the IMMI is compatible with all UR cobots, including the UR20 and new UR30. UR’s newest generation of cobots offer more extensive reach into bigger presses up to 750 tons at least. More commonly, machines of 400 tons or less are automated with UR cobots, Buse noted.

“The quality coming off of these industrial machines are definitely an eye opener for a lot of people,” says Klassen. “They weren't aware that 3D printing can really produce end-use products for consumers.”

Although the overall U.S. manufacturing sector ended 2023 on a sour note and has stayed there so far this year, one sliver of manufacturing called additive manufacturing, or 3D printing, is still riding the record highs it experienced in 2023.

While American companies still turn to China for low cost traditional manufacturing, Klassen says additive manufacturing prices coming out of China are very similar to what U.S. additive manufacturers can offer.

"Year over year, we're seeing a definite pickup in the amount of parts that are being made, and the amount of companies that are getting on board," says Scott Volk, owner and president of Advanced Additive Innovations (AAI), a North Carolina-based 3D printing service company. "It's actually a surprising amount of adoption I didn't really expect."

Further, because the cobot can operate without protective shielding, molders don’t have to sacrifice precious manufacturing space.

“For a small company like mine, the issue we have is administrative costs, so Craftcloud takes over the quoting process, order management, invoicing, and a large part of the customer service,” says Volk. AAI has become one of the top-reviewed companies on the Craftcloud platform, earning 4.89 out of 5 stars. “It's been really instrumental in building our business.”

Craftcloud's print volume will, by June, surpass one million 3D-printed parts for 2024, and Kring says that more companies than ever are applying to join its partner network.

“Plastic 3D printing has been around for about 35 years and that maturity is driving the adoption and commercial use that we’re seeing today,” says Volk.

UR’s Injection Molding Machine Interface (IMMI) has provided a new level of automation connectivity to the plastics industry since its introduction in 2020, said Christopher Buse, application engineer for UR. Because of the pandemic hiatus, NPE2024 was the first time the IMMI was shown at an NPE.

“We’ve watched customers get to know 3D printing with one-off parts and prototypes, but then realizing that they can actually use this technology for larger orders and end-use parts,” says Kring. “The other part of Craftcloud’s growth was definitely metal.”

This growth is reflected on the individual company level as well, with one of the largest additive manufacturing services, Xometry, which offers traditional manufacturing along with 3D printing, reporting a 22% year-over-year revenue growth in 2023. Industry competitor Protolabs also offers traditional manufacturing alongside 3D printing, and reported a revenue increase of 3.2% over 2022.

A 3D printing technician monitoring part fabrication at JawsTec, a 3D printing service company in ... [+] American Falls, Idaho.

Thanks for reading our community guidelines. Please read the full list of posting rules found in our site's Terms of Service.

In order to do so, please follow the posting rules in our site's Terms of Service. We've summarized some of those key rules below. Simply put, keep it civil.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly