Injection Molding: Faster, Smarter, More Efficient Machines Tackle

Author:gly Date: 2024-09-30

While many people still don’t know MIM by name, its products have followed people into their smartphones, cars and domestic appliances. MIM technology is a multi-step combination of traditional industrial technologies. Each step requires careful learning, observation, recording and operation. Due to its unique human resources and the nature of business in Greater China, the MIM industry has been able to adapt itself into just what its customers need.

Prof Shun-Tian Lin (Fig. 4) teaches in the Department of Mechanical Engineering, Taiwan University of Science and Technology. He returned to Taiwan from the United States in 1991 to promote the MIM of iron, stainless steel, copper and carbides, as well as ceramics. My master’s and PhD courses were guided by Prof Lin. His highest achievement is bridging the gap between PIM research and industry. Using his in-depth knowledge of a wide range of materials, he has guided many companies in Greater China to successfully integrate MIM and CIM technology into their products.

Editor in chief of PlasticsToday since 2015, Norbert Sparrow has more than 30 years of editorial experience in business-to-business media. He studied journalism at the Centre Universitaire d'Etudes du Journalisme in Strasbourg, France, where he earned a master's degree.

In life, some things develop naturally, and some are helped along by luck. The successful development of industrial technology also needs coincidence. These are some of the ‘coincidences’ that I believe had an impact on the development of MIM in China.

The patented FIM process uses high-speed Nexa3D printers and xMOLD resin to print injection molding tools that are compatible with thousands of off-the-shelf injection molding materials, including reinforced high-performance feedstocks. The process reduces design, iteration, and validation cycles using end-product materials to a matter of hours rather than weeks.

A technical session, comprising three papers, at the Euro PM2021 Virtual Congress, organised by the European Powder Metallurgy Association (EPMA) a...»

The COVID-19 pandemic, the US/China semiconductor trade war, and the wider semiconductor crisis led to reduced smartphone production, resulting in a reduction in the demand for MIM parts for this application. This resulting spare capacity led to an immediate production shift in Greater China. Small smartphone parts were replaced by components for domestic products, often larger in size. This shift was in part possible thanks to the low cost of Chinese MIM powders. This, combined with low domestic transport costs, has allowed raw materials and products to be produced nearer the point of demand, without the need for international shipping. The MIM industry in Greater China has, in this instance, proven itself resilient.

In terms of technical contribution, Prof Hwang was the one who advocated ASTM F75 alloys for smartphones; this alloy has since been used in the camera frames of over 500 million smartphones since 2016. He has published two textbooks, Powder Metallurgy (3rd ed.) and Metal Injection Molding (2nd ed.), both of which are widely used in industry and academia. However, he has often said that, while we can record our knowledge in such books, we should better appreciate the real-world skills, know-how and experiences which are key to making things happen and keeping the MIM industry strong and vibrant.

How has the global Metal Injection Molding industry weathered the most turbulent years in recent history, and what has the impact been on MIM’s k...»

Reach a truly international audience that includes component manufacturers, end-users, industry suppliers, analysts, researchers and more.

Design input collected from the first tests was integrated in a second iteration that took only a couple of hours to complete. By contrast, conventional metal tooling would have taken more than six weeks to design and procure, and the adjustments needed for the second iteration would have taken an in-house tool-shop a week to complete.

The 3D-printed molds for the first and second iterations cost less than €2,000 combined. And the technology enabled a two-day design cycle, which is more than 90% faster than conventional metal tooling.

The localisation of MIM equipment production began in about 2011 and hasn’t stopped since. More than five generations of batch vacuum sintering and debinding furnaces were developed in only a decade. The invention of oxalic acid catalytic debinding by Shenzhen SinterZone technology Co., Ltd. in 2014 was a big step towards reducing the environmental impact of the MIM debinding process. Ningbo HIPER Vacuum Technology Co., Ltd. advanced its batch vacuum sintering furnace technology to six-zone temperature control. Continuous sintering furnaces have also been manufactured for five years by Hiper and SinterZone.

Prof Kuen-Shyang Hwang (Fig. 3) teaches in the Department of Materials Science and Engineering, Taiwan University. He returned to Taiwan in 1988 from the United States, where he began his MIM research. All of Prof Hwang’s teachings and research are related to PM and MIM, an area in which he has mentored many students, many of whom are now in the MIM industry. Among these is Dr Y C Lu, Professor Hwang’s first PhD graduate, of Taiwan Powder Technology Co., Ltd. (TPT). TPT was the first company in Asia to produce MIM 3C products on a large-scale production order.

Today, a record number of rapid tooling producers exist with the ability to complete a set of four-cavity moulds within seven days, in order to provide prototypes to customers. Perhaps this is the main reason why the MIM industry does not use additively manufactured rapid prototypes. Many tooling factories in Greater China already operate highly efficient and automated ‘lights out’ production – this is a real enabler of the fast delivery times offered by the MIM industry.

SPT implemented Nexa3D’s Freeform Injection Molding (FIM) technology to help customers shorten time-to-market on complex medical devices in demanding medical-grade materials and to expand on the range of materials that can be quickly and reliably used in prototyping and early device test manufacturing.

As early as 1996, MIM was identified as one of the key technologies for the future of China’s manufacturing industry. MIM research and development programmes have been continuously supported by government programmes such as the National Natural Science Foundation of China (NSFC), the National High-Tech R&D Program of China (863 Program), the National Basic Research Program of China (973 Program), and the National Key Research and Development Program of China, to name just a few.

Freeform Injection Molding technology from Nexa3D compresses design, iteration, and validation cycle times into a matter of hours rather than weeks.

Although MIM technology has only existed for around half a century, it has been promoted in Greater China since 1985. The fortuitous combination of the many events and circumstances presented here has resulted in the Chinese MIM industry accounting for half of the world’s production. What is clear is that well-funded R&D centres, connected to industry by high-profile ‘technology champions’, all operating within a defined strategic national framework, can result in what, by any standards, is a major success story.

Certified to ISO 13485, Denmark-based SPT Vilecon describes itself as a fully integrated provider of development and manufacturing services to the medical device industry. It offers in-house tool making and injection molding along with other manufacturing services to companies in northern Europe.

When Apple launched its new iPhone 13, we were very happy to see that parts produced by Metal Injection Molding still featured heavily. While the company’s requirements for MIM parts are very demanding across the board, this is especially the case in terms of part complexity, tolerances and appearance. It is in the latter – in a part’s aesthetic features – where the capabilities of MIM products can often be best demonstrated. Their excellent metallic appearance and surface finish, in addition to a variety of special capabilities unique to certain alloys, all available at a relatively quick production speed, are some of the key factors in MIM’s rise in popularity. And the technology’s progress shows little sign of slowing, with the new generation of folding smartphones relying on metal injection moulded hinges to deliver stable, long term performance.

Discover suppliers of these and more in our advertisers’ index and buyer’s guide, available in the back of PIM International.

HP’s Metal Jet has undergone significant refinement in the years since it was first unveiled in 2018. Now, by incorporating nearly the whole Bind...»

The 2023 International Conference on Injection Moulding of Metals, Ceramics and Carbides (MIM2023), organised by the Metal Powder Industries Federa...»

I believe that we are all curious as to the reasons driving the rapid growth of the MIM industry in Greater China – including mainland China, Taiwan, Hong Kong, and Macau – in the last decade. Is success down to being in the right place at the right time, to a series of coincidences, or can individuals and governments, through strategic goals or individual efforts, drive the success of an industry? Here is my analysis.

The GBA is also home to a leading manufacturing innovation city: Shenzhen. While the region faces increasing competition for low-cost manufacturing from Southeast Asian countries such as India and Vietnam, as well as in rapid research and development for innovative electronics from Europe, the United States, and Japan, the industry here naturally aims to keep its name relevant through its MIM technology capabilities. With the ability to meet the needs of a large number of orders in a short amount of time, it slots into place with the product development and mass-production methods already established in the GBA.

Prof Xuanhui Qu (Fig. 5) teaches Powder Metallurgy at the School of Materials Science and Engineering, within the University of Science and Technology Beijing. He is a Chinese-educated scholar who, since the beginning of his professorship in 1992, has trained over one hundred postgraduate students, many of whom are active in the MIM industry, including engineers, CTOs and CEOs. He allows students to guide their own work – something very admirable amid potentially rigid academic life. Today, he is the president of the MIM Association of the China Powder Metallurgy Alliance (CPMA), as well as the president of Powder Metallurgy Committee of the Chinese Society of Metals. He has served as Editor in Chief of the journal Powder Metallurgy Technology, the longest-running Chinese PM journal, since 2010.

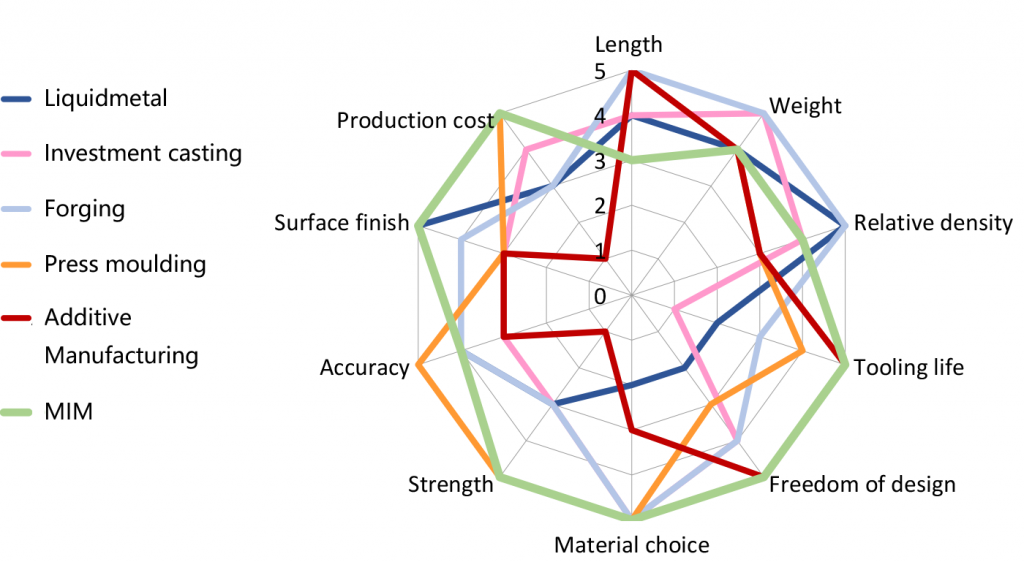

By the end of 2021, countries around the world will begin a new wave of energy regulation. This gives the MIM industry a powerful business opportunity as a relatively energy-efficient manufacturing process. MIM is highly flexible and offers many advantages for small parts manufacturing, especially in comparison to processes with high energy consumption and a negative environmental impact, such as die casting, lost-wax casting (investment casting), traditional casting, forging, etc (Fig. 9).

Medical device manufacturers are tasked with developing elaborate test protocols to ensure that the product in development is safe and meets essential requirements. If these tests are conducted late in the development process, the more onerous and risky they become. SPT Vilecon often works with silicone, a material that is extensively used in medical applications because of its chemical resistance, mechanical performance, and biocompatibility. However, silicone parts are notoriously difficult to prototype and test, since most grades need to be injection molded to achieve their full performance potential, said the company. FIM enabled SPT Vilecon to offer an alternative to a customer developing an intravenous (IV) silicone product — the use of 3D-printed tooling to perform early design and material verification at a fraction of the cost of conventional methods.

Injection-molded silicone parts were produced within two days, allowing early verification of key design and performance aspects.

The dissemination of knowledge is crucial when considering whether a new technology can be adopted by a region. I joined the MIM industry in 1991, one afternoon during the first week of my master’s degree, and, after thirty years in the field, I have come up with a list of the three most respected educators from Greater China who have played a key role in nurturing and developing the talent that enabled the industry’s success.

All these equipment innovations have been based on a desire for greater environmental protection, CO2 reduction, energy conservation, and safety. In addition to furnace technology, innovations have also been introduced that automate feedstock kneading and granulation, saving on labour costs.

In mainland China, there are two major triangular economic zones – the Pearl River and the Yangtze River deltas. Together, these are home to almost the entire capacity of Chinese manufacturing. Within the Pearl River Delta, the Greater Bay Area (GBA) represents nine cities from the Guangdong province, as well as the entirety of the Macau and Hong Kong regions (Fig. 1). This is the world’s most populous bay area – greater than San Francisco, New York, and Tokyo – and alone represents one of the largest economies in the world. The GBA hosts the greatest number of MIM plants in Greater China.

The free-to-access PIM International magazine archive offers unparalleled insight into the world of MIM, CIM and sinter-based AM from a commercial and technological perspective through:

Greater China has a lot of plastic injection moulding companies, meaning there are also quite a few corresponding injection moulding tooling factories. Although the tooling used for MIM and plastic injection moulding are different, a ‘general’ injection moulding tooling factory may still have experience manufacturing some sets of MIM tools. Moreover, these factories can quickly learn the specific manufacturing expertise needed for MIM tools, and expand production.

In early 2008 in China, a severe winter blizzard paralysed transportation and affected hundreds of millions of people preparing to return home for the Chinese New Year. The weather also worsened the ongoing economic depression at that time, as workers were left unable to return to their workplaces. Following this crisis, the Chinese government began to focus on the improvement and construction of the country’s transportation infrastructure – power networks, communications, roads, railways, and water supply. After ten years of construction, the foundations of the relevant transportation systems had been transformed. Connected with this, the MIM industry found the opportunity to benefit not only from increased government funding, leading to rapid adoption by a variety of sectors, but it also directly benefited from the new, faster, more efficient transportation networks.

Based on input collected from the first two iterations, the design of the silicone part was approved and manufacturing of a metal tool was initiated with full confidence of part moldability and performance. The in-house tool shop built the final metal tooling in four weeks without iterations.

Robust and valid prototyping and verification are key to minimizing cost, time, and risk factors in developing medical devices, said SPI Vilecon. FIM is a new toolbox for medical device companies seeking to accelerate their innovation and obtain early verification of part performance and moldability, added the company.

Of course, it is not always ‘plain sailing’: equipment manufacturers are working day and night, both to fulfil equipment orders and develop new equipment, and many MIM factories use the current intermittent power supply situation to complete customer orders – including the author himself, as I write this manuscript. Welcome to Greater China and its MIM family!

SPT Vilecon said it has begun expanding the range of injection mold prototyping with silicone, metal, and ceramic materials to provide medical device manufacturers with an even wider selection of product development and verification services.

With the support of these R&D programmes, great progress has been made in basic research, from alloy selection, to binder design, fundamental process research and so on. The success of this basic research has established a substantial foundation for the rapid development of China’s MIM industry.

Don't miss any new issue of PIM International, and stay up to date with the latest industry news. Sign up to our fortnightly newsletter.

Extensive MIM, CIM industry and sinter-based AM industry news, plus the following exclusive deep-dive articles and reports:

One could be mistaken for thinking that the materials used by MIM today are based on quite long-established specifications such MPIF Standard 35. Don’t overlook the fact that, historically, industrial powder production had never been able to atomise high percentages of d50 < 15 µm fine powder. The production of MIM grade powders is as high as ever. At least ten powder manufacturers in China produce more than 2,500 tons of MIM powder a year – there is even one small factory with a single atomiser, yet it can also produce 250 tons of MIM powder a year. This easy sourcing of raw materials has therefore also been a major boost for MIM’s development.

The rise of MIM technology can be viewed in parallel to the rise of smartphones. With perhaps the same global impact as the adoption of fire, smartphones have changed human civilisation. They allow unprecedented information transmission and clearer, more widespread communication than ever before. Of course, this universal electronic device needs to be strong, functional and aesthetically appealing. MIM products provided the necessary structural strength for this whilst having the desired aesthetically appealing appearance (Figs. 6–8).

A supplier of development and manufacturing services to medical device OEMs used Freeform Injection Molding from Nexa3D to accelerate time-to-market and slash prototyping costs for a complex silicone-based IV device. SPT Vilecon explained the process in a recent press release.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly