Injection molding company installs solar to slash energy costs - plastic injecti

Author:gly Date: 2024-09-30

While we only use edited and approved content for Azthena answers, it may on occasions provide incorrect responses. Please confirm any data provided with the related suppliers or authors. We do not provide medical advice, if you search for medical information you must always consult a medical professional before acting on any information provided.

In 2020, the PC accounted for the largest market share in material type segment and is also projected to a moderate growth during the forecast period. The market growth is expected to be fueled by the increasing usage of modern medical devices, micro components for the electric vehicles and various components for electronics industry.

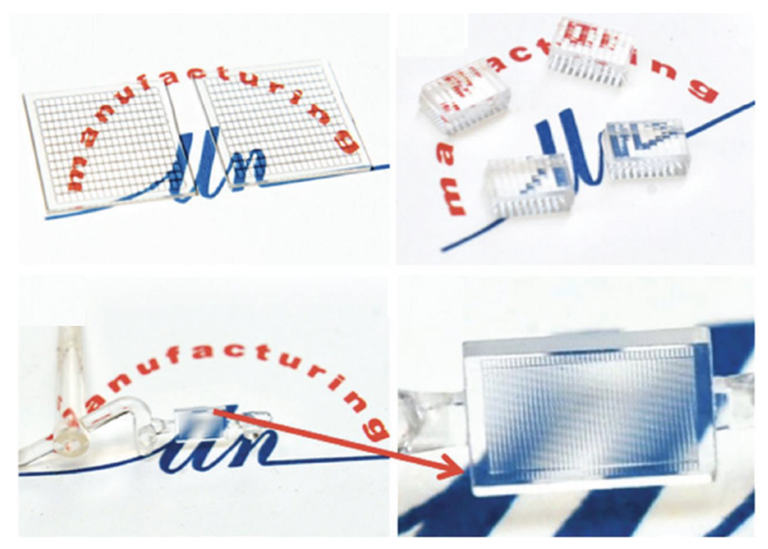

Industrial microinjection molding trials revealed significant issues with using conventional injection molding techniques, including long cycle times, process inconsistencies, material waste, and residence problems. Other problems include the demanding tolerances needed for micro-molded parts and in the case of polymeric microdevices, the untoward modification of their properties and microstructure.

Davey, Reginald. (2022, September 22). Fabricating Polymeric Microdevices with Microinjection Molding. AZoM. Retrieved on September 27, 2024 from https://www.azom.com/news.aspx?newsID=60056.

Davey, Reginald. "Fabricating Polymeric Microdevices with Microinjection Molding". AZoM. https://www.azom.com/news.aspx?newsID=60056. (accessed September 27, 2024).

Micro molds are utilized for various medical processes. Few of the medical molds include surgical devices, endoscopic devices, catheters, hearing aids, point of care testing devices, diabetes management devices, DNA research and sequencing devices, electronic components for medical devices, microfluidics, and pharmaceutical applications, including drug delivery devices, vials, caps, specimen cups, blood collection tubes, syringes, and IV parts. The shifting trend towards miniaturization and nanotechnology in the medical sector is fueling the demand for compatible micro-molds for every medical application.

The key players profiled in the Micro Injection Molded Plastic Market report include Accumold LLC (US), Isometric Micro Molding, Inc. (US), Makuta Micro Molding (US), Precimold Inc. (Canada), MTD Micro Molding (US), Microsystems Precision Medical Moulds (UK), Veejay Plastics Injection Molding Company (US), Knightsbridge Plastics Inc.(California), Polymermedics Ltd. (UK), Manner Solutions For Plastics (Germany), Microdyne Plastics, Inc. (US), SMC Ltd. (US), Mikrotech (US), Sovrin Plastics (UK), Stack Plastics (US), American Precision Product(US), D&M Plastics, LLC (US), Paragon Medical (US), Micro Molding Inc. (US), Spectrum Plastics Group, Inc. (US), Matrix Plastic Products (US), Yomura Technologies Inc (Taiwan), and Barnet Intelligent Materials (US).

Polymeric micro- and nano-features require high quality and consistent replication to ensure the performance of devices. The critical problems with conventional injection molding techniques have led to a significant research focus on equipment development and parameter optimization techniques. Micro-molding technologies based on reciprocating screws, plungers, and multi-stage systems have been developed over the past twenty years.

Developments in semiconductor fabrication methods could produce larger substrates with nano- and micro-scaled surface features. In current research, the multi-scale fabrication of integrated surface features on metallic substrates and inserts has not been widely reported. Commercial microfluidic devices urgently need research into in-line functionality integration.

CHICAGO, Feb. 3, 2022 /PRNewswire/ -- According to the new market research report "Micro Injection Molded Plastic Market by Material Type (Liquid-Crystal Polymer (LCP), Polyether Ether Ketone (PEEK), Polycarbonate (PC), Polyethylene (PE), Polyoxymethylene (POM)), Application and Region - Global Forecast to 2026" published by MarketsandMarkets, the Micro Injection Molded Plastic Market is projected to reach USD 1,692 million by 2026, at a CAGR of 11.2% from USD 995 million in 2021. Micro injection molded plastics are made of micro injection molding technique which is a highly specialized manufacturing process that produces extremely small, high-precision thermoplastic components with micron tolerances, which can be used in various industries such as medical, automotive, electronics and others.

![]()

The global semiconductor market has entered an exciting period. Demand for chip technology is both driving the industry as well as hindering it, with current chip shortages predicted to last for some time. Current trends will likely shape the future of the industry, which is set to continue to show

The technique was initially developed in the late 1980s, but in the early stages of its development, no appropriate machine technologies were available. Modified conventional injection molding machines with hydraulic drive functions were used to replicate high-aspect-ratio micro-scaled parts. Producing reliable and functional microdevices was highly challenging.

In recent years, the IoT is rapidly being introduced into almost all sectors, but it has particular importance in the EV industry.

Reg Davey is a freelance copywriter and editor based in Nottingham in the United Kingdom. Writing for AZoNetwork represents the coming together of various interests and fields he has been interested and involved in over the years, including Microbiology, Biomedical Sciences, and Environmental Science.

Micro Injection Molding Machine Market by Type (0-10 tons, 10-30 tons and 30-40 tons), Application (Medical, Automotive, Fiber Optics, Electronics), and Region (APAC, North America, Europe, MEA, South America) - Global Forecast to 2026 https://www.marketsandmarkets.com/Market-Reports/micro-injection-molding-machine-market-245710637.html

In this interview, Prolific North's Managing Director Alexandra Balazs discusses the launch of the inaugural STEM Marketing Awards, sharing insights into why they’re crucial for the sector and how they aim to shape the future of STEM marketing.

Furthermore, studying nano- and micro-scaled surface features produced using microinjection molding processes on large substrates and exploring process optimization routes and quality control will have huge practical value for future research. Quality control and process optimization research will also have use for standalone polymer microdevices.

Overall, the review has highlighted the key progress in this field in recent years, and the authors have noted that fundamental development in the field of polymeric microdevice microinjection molding has generated novel micro-scaled devices, vast amounts of process knowledge, and know-how for product development in the future.

View detailed Table of Content here - https://www.marketsandmarkets.com/Market-Reports/micro-injection-molded-plastic-market-81256553.html

Medical is the largest application for micro injection molded plastic. In the micro injection molding industry, medical micro molding is a highly specialized sector. As medical equipment gets more miniaturized, they rely on micro injection molded components to provide crucial patient care both within and outside the body.

In this interview, AZoM talks to Philippe Wilson about benchtop NMR and its role in different fields, focusing on its main use in biofluid analysis.

Microinjection molding of polymeric microdevices is a field that is still in its relative infancy, but significant advances have been made in recent decades. The paper in Micromachines has provided a review of current state-of-the-art perspectives on the technology and the properties of polymeric microdevices produced using microinjection molding techniques.

Microdevices have gained research attention in the fields of biomedicine and optics, with progress made in recent years toward mass production and commercialization. Devices can be constructed from several materials such as glass, ceramics, metals, and polymers.

The review paper has provided a comprehensive knowledge base for future researchers in the field of polymer microdevice design and manufacture. Microinjection molding is playing an increasingly central role in the production of these advanced micro-scaled devices. Whilst several key challenges still exist, huge potential exists for the design of innovative, advanced devices in fields such as biomedicine, optics, and diagnostics.

Like any field of technology, however, there are several limitations in this field that must be overcome to ensure mass production and widespread commercial viability of polymeric microdevices produced via microinjection molding methods. The review has highlighted several key challenges.

Measure material stiffness and resiliency with precision up to 10,000 units with Taber's Stiffness Tester. Learn more here.

The global anti-drone market was valued at USD 2.16 billion in 2024 and is projected to reach USD 7.05 billion by 2029; it is expected to register a...

According to Institute of Industrial Technology and Automation (ITIA-CNR), Micro-components are often smaller than a single grain of granulate. Micro injection molded plastic components are of shot weights of 1 to 0.1 g with tolerances in the range of 10 to 100 microns. This molding process allows manufacturers to produce complicated small geometries with maximum possible accuracy and precision.

Comparison of surface areas: a 1 cm3 volume is composed of 1 cm, 1 mm, and 1 nm cubes. Image Credit: Zhang, H et al., Micromachines

The global Age-related Macular Degeneration drugs market is set to grow from USD 10.46 billion in 2024 to USD 17.37 billion by 2029, reflecting a...

Davey, Reginald. 2022. Fabricating Polymeric Microdevices with Microinjection Molding. AZoM, viewed 27 September 2024, https://www.azom.com/news.aspx?newsID=60056.

Europe is the second-largest consumer of micro injection molded plastic, in 2020. Germany, France, the UK are key countries considered in the European region. Increased consumer spending and exports drive the region's economy. Europe has a well-developed automotive sector. It is one of the largest producers of commercial vehicles and has a strong spare parts industry as well. It offers an ideal logistics platform for companies to export to international markets. Europe is an important market for Japanese and US car manufacturers looking to strengthen their position in Europe. Macroeconomic factors such as the recovery of the economy, rising domestic demand, and increase in consumer spending and exports are expected to drive the economic growth of Europe.

Zhang, H, Liu, H & Zhang, N (2022) A Review of Microinjection Moulding of Polymeric Micro Devices Micromachines 13 (9) 1530 [online] mdpi.com. Available at: https://www.mdpi.com/2072-666X/13/9/1530

Kai Düffels from Microtrac discusses the CAMSIZER 1, a particle size analyzer designed for simplicity. Read the interview here.

Your questions, but not your email details will be shared with OpenAI and retained for 30 days in accordance with their privacy principles.

"PC is estimated to be the fastest-growing material type in the Micro Injection Molded Plastic Market between 2021 and 2026."

Contact Mr. Aashish MehraMarketsandMarkets™ INC.630 Dundee RoadSuite 430Northbrook, IL 60062USA: 1-888-600-6441Email: sales@marketsandmarkets.com Visit Our Website: https://www.marketsandmarkets.com/ Content Source: https://www.marketsandmarkets.com/PressReleases/micro-injection-molded-plastic.asp Research Insight: https://www.marketsandmarkets.com/ResearchInsight/micro-injection-molded-plastic-market.asp

Using polymeric microdevices for nano- and micro-scaled surfaces on devices such as microfluidic chips significantly increases their surface-to-volume ratio, which improves their performance. Significant research progress has been made in recent years in designing polymer microdevices, both as standalone applications and as surface components for other micro-scaled devices.

MarketsandMarkets's flagship competitive intelligence and market research platform, "Knowledge Store" connects over 200,000 markets and entire value chains for deeper understanding of the unmet insights along with market sizing and forecasts of niche markets.

The recent expansion in applications for polymeric microdevices in areas such as biomedicine, lab-on-a-chip technologies, and micro-optics has inspired research on various perspectives of microinjection molding technologies. Process optimization, machine and mold design, numerical simulations, polymeric microdevice properties, morphologies, rheology, and advanced applications have been explored extensively.

MarketsandMarkets™ provides quantified B2B research on 30,000 high growth niche opportunities/threats which will impact 70% to 80% of worldwide companies' revenues. Currently servicing 7500 customers worldwide including 80% of global Fortune 1000 companies as clients. Almost 75,000 top officers across eight industries worldwide approach MarketsandMarkets™ for their painpoints around revenues decisions.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Writing in the journal Micromachines, a team of scientists from Beijing University of Technology and University College Dublin has investigated current perspectives on microinjection molding of polymeric microdevices.

Finally, optimization of the entire process chain has vast potential for this field, and integrating industry 4.0 technologies can aid the industrial scale mass production of complex microinjection molded polymer microdevices.

Davey, Reginald. "Fabricating Polymeric Microdevices with Microinjection Molding". AZoM. 27 September 2024.

Our 850 fulltime analyst and SMEs at MarketsandMarkets™ are tracking global high growth markets following the "Growth Engagement Model – GEM". The GEM aims at proactive collaboration with the clients to identify new opportunities, identify most important customers, write "Attack, avoid and defend" strategies, identify sources of incremental revenues for both the company and its competitors. MarketsandMarkets™ now coming up with 1,500 MicroQuadrants (Positioning top players across leaders, emerging companies, innovators, strategic players) annually in high growth emerging segments. MarketsandMarkets™ is determined to benefit more than 10,000 companies this year for their revenue planning and help them take their innovations/disruptions early to the market by providing them research ahead of the curve.

Firstly, optimizing mold design to replicate high-quality devices with enhanced features and functionalities is a key technical challenge. Reliable, advanced vacuum venting systems and temperature control systems for molds need to be designed.

Several studies have evaluated manufacturing processes for polymeric microdevices, with microinjection molding emerging as a suitable method. Advances in technology have made it a preferred high-volume manufacturing technique.

The primary distinction between graphene-based batteries and solid-state batteries lies in the composition of either electrode. Although the cathode is commonly changed, carbon allotropes can also be employed in fabricating anodes.

Perspectives on equipment, processes, tooling, nano- and micro-scale replication, and applications have been highlighted. Additionally, the rheological properties, mechanical properties, and morphologies of polymeric devices are comprehensively reviewed by the authors.

Several innovative applications have been explored for microdevices including drug delivery systems such as microneedles, diagnostic microfluidic devices, medical implants, devices with functional nano/microstructured surfaces, and micro-optics. Devices can be designed with complex microstructures and novel functionalities.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly