Injection Molding Companies – The Best Companies On The Market - best injection

Author:gly Date: 2024-09-30

The good thing is that if you have a machine running with monolayer, you can retrofit this machine with a new W. Müller head to process with DeCo or ReCo. With a multilayer head from W. Müller, you have the flexibility to run either multilayer or monolayer bottles with that same head.

A significant drawback, however, is the fact that there are design limitations inherent in injection molding, with some geometries being difficult to remove from the mold, and precise and delicate designs being difficult and expensive to mold accurately. Also, it is difficult, costly and sometimes impossible to correct tooling mistakes or change tooling to optimize or iterate new designs. Often, new tools are required, with all this implies in terms of cost and time—tools often taking weeks if not months to fabricate.

Exhibitors and presenters at the plastics show emphasized 3D printing as a complement and aid to more traditional production processes.

The good news is that the average real-world scenario lies somewhere in between the best and worst case scenarios described above. However, if it was possible to make the worst case scenario processable with three-layer technology, then there is a lot of hope for most recycled blow molding materials out there.

Depending on the virgin material and the PCR material being used, the virgin bottle will most likely have the highest topload strength and the PCR monolayer bottle will have the lowest topload. With the ReCo structure you will see an improvement in the topload strength.

While prices moved up for three of the five commodity resins, there was potential for a flat trajectory for the rest of the third quarter.

3D printing exhibits a number of advantages when compared to legacy processes such as injection molding. The most important of these is the added flexibility 3D printing allows in design.

Mixed in among thought leaders from leading suppliers to injection molders and mold makers at the 2023 Molding and MoldMaking conferences will be molders and toolmakers themselves.

While the major correction in PP prices was finally underway, generally stable pricing was anticipated for the other four commodity resins.

Conversely, injection molding makes design iterations costly. Beyond the high cost of upfront tooling, which as mentioned increases the more complex the part, production is restricted to the location of the production tooling. 3D printing technologies manufacture direct from 3D CAD files, so the location of manufacture is much more flexible.

Introduced by Zeiger and Spark Industries at the PTXPO, the nozzle is designed for maximum heat transfer and uniformity with a continuous taper for self cleaning.

Have you ever thought about how materials are sorted and why a lot of PCR materials are gray? When used plastic arrives at the sorting facility, white HDPE bottles usually will be sent to the white HDPE stream and colored bottles will be sent to the colored stream. Because all colors sent to the colored stream are mixed together, the resulting color of this mixture is gray. Depending on the colors sent, you get different shades of gray, but gray nonetheless. Because of the different shades of white and natural-color bottles entering the white stream, the result is a whiteish ivory material (Fig. 5).

The only way to achieve widespread circularity is to find a place for those gray materials in PCR bottles. Does that mean that on your next trip to the drugstore you will only find gray PCR bottles? Not with our ReCo technology adding a virgin layer with color on the outside to cover the gray PCR material. With the DeCo and ReCo technologies, it is possible to use those gray PCR materials in nicely colored bottles. How much PCR can you use in this way? It depends on the technology and regrind use, but normally up to 80% in DeCo without regrind and up to 70% in ReCo without regrind or about 60% with regrind.

FIG 8 – Topload strength comparison of virgin (left), monolayer PCR (center) and ReCo bottle with PCR (right). Source: W. Muller GmbH

Most obviously, 3D printing can make components either impossible or expensive and difficult to achieve using injection molding, such as components that are hollow in certain areas. This is possible, as in 3D printing material is added in layers, and material density of the core can be altered. So, not only can some areas be hollow, but other critical areas can be reinforced. This means that 3D printing is a key facilitator when it comes to lightweighting, but with increased strength.

Across all process types, sustainability was a big theme at NPE2024. But there was plenty to see in automation and artificial intelligence as well.

When processing PCR, precision in the design of both the head and extruder is paramount to accommodate the necessary multilayer configurations. This precision ensures exceptional tolerance for MFI fluctuations, which is crucial when transitioning between materials and colors. Ensuring that settings remain valid across transitions minimizes downtime spent adjusting parameters, thereby maximizing productive output.

At W. Müller, we are known for our production of extrusion heads for blow molding machines. What many may not realize is that we operate two technical centers that have provided us with early access to recycling materials in collaboration with material manufacturers and recyclers to conduct comprehensive tests under varying conditions. Over the years, we've evaluated more than 50 different recycled materials from over 15 manufacturers globally, testing them across all our technologies, from one to seven layers, in bottles from 70 ml to 1 L. This research has also enabled us to observe the evolution of commercially available PCR materials over time.

The 3D printing machines that achieve production level repeatability and accuracy are typically costly beasts. Because of this, many potential users are put off by the large capital outlay required, and therefore approach 3D printing subcontract specialists, who not only have the levels of necessary high-quality 3D printing machines in-house but also the experience to get the most out of them.

With multilayer technologies, it is possible to improve the mechanical properties of bottles while using PCR materials. A colored outer layer enables you to cover gray and black PCR materials, black specks and impurities, while saving in masterbatch and getting a color closer to your original color.

FIG 3 – W. Muller’s two-layer DeCo technology facilitates coloring the bottle at minimum cost while hiding the PCR layer. Source: W. Muller GmbH

Second quarter started with price hikes in PE and the four volume engineering resins, but relatively stable pricing was largely expected by the quarter’s end.

Plastics Technology’s Tech Days is back! Every Tuesday in October, a series of five online presentations will be given by industry supplier around the following topics: Injection Molding — New Technologies, Efficiencies Film Extrusion — New Technologies, Efficiencies Upstream/Downstream Operations Injection Molding — Sustainability Extrusion — Compounding Coming out of NPE2024, PT identified a variety of topics, technologies and trends that are driving and shaping the evolution of plastic products manufacturing — from recycling/recyclability and energy optimization to AI-based process control and automation implementation. PT Tech Days is designed to provide a robust, curated, accessible platform through which plastics professionals can explore these trends, have direct access to subject-matter experts and develop strategies for applying solutions in their operations.

In a time where sustainability is no longer just a buzzword, the food and beverage packaging industry is required to be at the forefront of this innovation. By adopting circular packaging processes and solutions, producers can meet regulatory requirements while also satisfying consumer demand and enhancing brand reputation. Join Husky to learn more about the broader implications of the circular economy — as well as how leading brands are leveraging this opportunity to reduce costs, increase design flexibility and boost product differentiation. Agenda: The cost and operational benefits of embracing circularity Key materials in circular packaging — including rPET and emerging bioplastics How to design a circular food and beverage package Strategies for selecting sustainable closures to future-proof packaging solutions Optimization and streamlining of production processes for enhanced efficiency How Husky Technologies can enable your sustainable success

FIG 2 – A variety of multilayer technologies are available to provide specific functions – aesthetic, functional and/or processing-related. Source: W. Müller GmbH

Conversely, some recycled materials present formidable challenges. In one case, we tested a PCR material for a recycler. We started with monolayer construction. As soon as the material came out of the die, it was obvious that that was not a material for blow molding. It produced a foamed, black/green parison with a lot of fumes, a horrible smell and some sort of oil dripping out and sticking to the die, pin and blow pin. The bottle? Nonexistent. The rough foam structure would not allow a bottle to be formed. What was supposed to be a 1 L round bottle looked like an ugly flower vase instead (see Fig. 1).

W. Müller’s two technical centers have evaluated more than 50 different recycled materials from over 15 manufacturers globally, testing them in one to seven layers, in bottles from 70 ml to 1 L.

DeCo and ReCo offer monomaterial multilayer solutions for processing PCR, ensuring recyclability while maintaining product integrity. DeCo consists of two layers, usually a thicker PCR inner layer and a thinner outer layer with virgin material and color masterbatch (Fig. 3). This enables you to color your bottle and hide the PCR while minimizing the use of masterbatch. The layers are easily customizable, so you can vary the thickness depending on your needs.

In addition, while there is an increasing number of material options that can be used with 3D printing, it still cannot match the choice of materials compatible with injection molding.

Adding coextruded outer and inner layers did not contribute much. This PCR material had some nylon in it, which has a higher melting point than HDPE. The unmelted nylon, together with the rough foam structure, still caused big holes in the bottles. After many tries with drying, filtering and changing processing parameters, it was possible to make three-layer bottles with 50% of this material in the center layer.

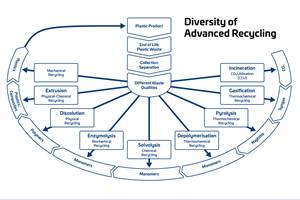

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

The goal was to recognize and capture these differences objectively, and see if it is possible to reduce them. This project was a cooperation between the additive producer Baerlocher, recycler PreZero (active in Europe and the U.S.) and W. Müller. Baerlocher provided the additive Baeropol RST, which is made from a combination of commonly used, nonantioxidant polymer additives that together support polymer stability. This additive was compounded into a batch of PreZero PCR HDPE material. Then, batches of PCR HDPE with and without additive were sent to W. Müller for testing.

Resin drying is a crucial, but often-misunderstood area. This collection includes details on why and what you need to dry, how to specify a dryer, and best practices.

This is based on the fact that today, 3D printing technologies have been refined to such an extent that they are truly viable production technologies. Now the conversation among manufacturers is around the most judicious use of 3D printing for production, what its advantages are, where the sweet spot is in terms of preferable volumes, what are the opportunities that exist through it use, and what are the barriers to entry?

Learn about sustainable scrap reprocessing—this resource offers a deep dive into everything from granulator types and options, to service tips, videos and technical articles.

At W. Müller, our team meticulously optimizes the channels of the head to streamline plastic flow, preventing the accumulation of deposits and abrasions. Neglecting this crucial step can lead to the introduction of additional black specks that may be erroneously attributed to the PCR material itself.

3D printing is unique as a disruptive technology in one key respect, and that is having disrupted the manufacturing paradigm through the introduction of rapid prototyping some 25 to 30 years ago. It is disrupting manufacturing again.

On our lab machine, cameras were installed on the front and on the side to take a picture of the parison at the same point during each cycle, which software analyzed to calculate the parison length. The gross and net weight of each bottle were measured, and the melt pressure in the extruder was controlled.

Some cheaper, more available HDPE PCR materials will have some PP in them. This comes from, for example, caps that were not sorted out properly. PP in HDPE will cause problems with the welding seam, which will not close properly. This will cause problems in the drop test, where the bottle will probably break at the welding seam.

The aim of this presentation is to guide you through the factors and the numbers that will help you determine if a robot is a smart investment for your application. Agenda: Why are you considering automation? What problems are you trying to solve? How and why automation can help Crunch the numbers and determine the ROI

Mike Sepe has authored more than 25 ANTEC papers and more than 250 articles illustrating the importance of this interdisciplanary approach. In this collection, we present some of his best work during the years he has been contributing for Plastics Technology Magazine.

With 3D printing, ideal material conditions throughout a part are dictated by design, not by the vagaries of various production and post-production processes used.

These respective sweet spots are quite discrete and play to the fact that forward-thinking manufacturers could in fact be looking at 3D printing and injection molding as complementary processes rather than competitive processes. When used constructively together, for example, pre-production cycles can be dramatically shortened before large volume production is undertaken.

When, how, what and why to automate — leading robotics suppliers and forward-thinking moldmakers will share their insights on automating manufacturing at collocated event.

Thousands of people visit our Supplier Guide every day to source equipment and materials. Get in front of them with a free company profile.

FIG 6 – Compare colors of a monolayer PCR bottle with 6% masterbatch (left), monolayer virgin bottle (center) with the same amount of masterbatch, and ReCo bottles with different three-layer structures and equal or lower masterbatch levels in just the outer virgin layer. Source: W. Muller GmbH

ReCo is a three-layer technology with a thinner outer layer, usually virgin with masterbatch; a thicker main or center layer, usually PCR with regrind; and an inner layer, usually just virgin (Fig. 4). The goal here is to save masterbatch, cover the PCR material, avoid contact between your product and the PCR, and improve the mechanical properties of the bottle.

FIG 1 – On left is a monolayer bottle of 100% PCR whose contaminants caused foaming and bottle distortion. On right is a three-layer ReCo bottle with the same PCR in the center main layer, while inner and outer virgin layers provide processing and mechanical stability and aesthetic appearance. Source: W. Müller GmbH

For extrusion blow molders, challenges of price and availability of postconsumer recycled resins can be addressed with a variety of multilayer technologies, which also offer solutions to issues with color, processability, mechanical properties and chemical migration in PCR materials.

When processing multilayer materials, achieving uniform material distribution is vital. Poorly designed heads lead to inconsistencies in distribution, which lead to variations in layer thicknesses, resulting in either overuse of more expensive materials or localized thinning of inner layers in the final product, potentially leading to increased migration risks. Therefore, meticulous attention to material distribution is essential to ensure both cost-effectiveness and product quality. This is achieved through the use of simulation software, which enables us to model the flow channels and identify potential design issues before manufacturing begins. By simulating the flow dynamics, we can pinpoint and address any problematic areas, ensuring optimal material distribution and minimizing the risk of uneven layer thicknesses. This proactive approach not only enhances product quality but also saves valuable time and resources by mitigating issues before they arise during production.

Beyond non-costly part complexity, using 3D printing for production also facilitates nearly unlimited geometric freedom, exhibits very low to zero iteration costs, and has low downtime in the production cycle.

When it comes to producing plastic parts, 3D printing is working in a space where the conventional processing technology is injection molding.

FIG 9 – In drop tests, monolayer gray PCR bottle (left) split at the weld seam after two falls, while white ReCo bottle with PCR in main layer (right) survived five falls intact. Source: W. Muller GmbH

Join KraussMaffei for an insightful webinar designed for industry professionals, engineers and anyone interested in the manufacturing processes of PVC pipes. This session will provide a comprehensive understanding of the technology behind the production of high-quality PVC pipes: from raw material preparation to final product testing. Agenda: Introduction to PVC extrusion: overview of the basic principles of PVC pipe extrusion — including the process of melting and shaping PVC resin into pipe forms Equipment and machinery: detailed explanation of the key equipment involved — such as extruders, dies and cooling systems — and their roles in the extrusion process Process parameters: insight into the critical process parameters like temperature, pressure and cooling rates that influence the quality and consistency of the final PVC pipes Energy efficiency: examination of ways to save material and energy use when extruding PVC pipe products

It is of course possible to use a gray PCR material in a multilayer bottle and color the outer layer white. This is not recommended because the bottle would end up contaminating the white stream with gray materials.

Follow these best practices to minimize loss of time, material and labor during color changes in molding containers from bottles to jerrycans. The authors explore what this means for each step of the process, from raw-material infeed to handling and reprocessing tails and trim.

Join this webinar to explore the transformative benefits of retrofitting your existing injection molding machines (IMMs). Engel will guide you through upgrading your equipment to enhance monitoring, control and adaptability — all while integrating digital technologies. You'll learn about the latest trends in IMM retrofitting (including Euromap interfaces and plasticizing retrofits) and discover how to future-proof your machines for a competitive edge. With insights from industry experts, it'll walk you through the decision-making process, ensuring you make informed choices that drive your business forward. Agenda: Maximize the value of your current IMMs through strategic retrofitting Learn how to integrate digital technologies to enhance monitoring and control Explore the benefits of Euromap interfaces and plasticizing retrofits Understand how retrofitting can help meet new product demands and improve adaptability Discover how Engel can support your retrofitting needs, from free consultations to execution

Many of you hear “multilayer” and immediately think that multilayer is bad for recycling. That is only true if you combine different polymers with a fairly large proportion of the minor component — for example, more than 6% EVOH oxygen barrier in an HDPE bottle. However, W. Müller heads are capable of making bottles with EVOH layers under 6%, which give you a fully recyclable bottle with a barrier.

The Plastics Industry Association (PLASTICS) has released final figures for NPE2024: The Plastics Show (May 6-10; Orlando) that officially make it the largest ever NPE in several key metrics.

For the topload test, three bottles were produced: a virgin monolayer bottle, a PCR monolayer bottle, and a ReCo three-layer bottle with 70% PCR in the main (center) layer. This same test has been done with different bottle geometries and sizes.

FIG 5 – When HDPE waste arrives at a sorting facility, white bottles are segregated into one stream that becomes white or ivory PCR pellets (left), while all other colors are combined into a stream that becomes gray pellets (right). Source: W. Muller GmbH

Despite price increase nominations going into second quarter, it appeared there was potential for generally flat pricing with the exception of a major downward correction for PP.

In this collection of content, we provide expert advice on welding from some of the leading authorities in the field, with tips on such matters as controls, as well as insights on how to solve common problems in welding.

Nonetheless, this high-quality PCR has two big problems: price and availability. A big effort goes into sorting, cleaning and removing volatiles from waste to make that PCR material. All this takes energy and resources, which are reflected in a high price per pound. If price is not an insurmountable obstacle, then you will face the next problem: After sorting so much waste out of the stream to get pure HDPE, the yield of high-quality material is relatively small. If everyone decides to make a 100% PCR bottle out of these premium PCR materials, there will only be enough material available for a few customers.

A test was performed where a virgin bottle, a PCR monolayer bottle, and a ReCo bottle were each dropped a maximum of five times from 6.5 feet. The virgin bottle survived all five falls without breaking, while the PCR monolayer bottle broke after about two falls. The inner and outer layers of the ReCo bottle helped stabilize the bottle, and thus the bottle survived all five drops, just like the virgin bottle (Fig. 9).

The idea that 3D printing is a plug-and-play technology is a myth. Entry-level desktop model printers only require a modicum of knowledge to operate. But for production applications, achieving the necessary build parameters, quality, costs per part and timeliness of build requires a heap of experience, which subcontract agencies have in spades.

We also observed that fewer substances migrated from the ReCo bottle. Many of the substances migrating from the monolayer bottle could not be found in the test of the ReCo bottle. The substances that would still be found migrating from the ReCo bottle had, in most cases, a lower concentration. Only two substances were found in higher concentrations from the ReCo bottle than the monolayer bottle. These substances were additives that migrated from the virgin layer.

It is tempting to buy those ivory colors and then add some color to make a nice PCR bottle. This is not the best approach to close the loop because you are taking material from the limited white stream and on the next product life cycle returning it to the gray stream, which few will want. If you buy the ivory PCR and mix in some white, then the bottle will end up again in the white stream and the loop is closed.

The Regulation (EC) No 1935/2004 is an EU legislation that governs the general requirements for materials and articles intended to come into contact with food. It establishes the principles and procedures for assessing the safety of such materials and articles, and includes provisions for labeling and traceability. Our tests were performed according to that legislation. They measure the migration of substances from the plastic material into the contents of the container. These results were evaluated for use in cosmetics containers.

Multiple speakers at Molding 2023 will address the ways simulation can impact material substitution decisions, process profitability and simplification of mold design.

Mold maintenance is critical, and with this collection of content we’ve bundled some of the very best advice we’ve published on repairing, maintaining, evaluating and even hanging molds on injection molding machines.

In this collection of articles, two of the industry’s foremost authorities on screw design — Jim Frankand and Mark Spalding — offer their sage advice on screw design...what works, what doesn’t, and what to look for when things start going wrong.

Furthermore, DeCo and ReCo are multilayer technologies that use only one polymer type (such as only HDPE or only PP), which makes the bottle 100% recyclable in any recycling stream.

Successfully starting or restarting an injection molding machine is less about ticking boxes on a rote checklist and more about individually assessing each processing scenario and its unique variables.

Many customers have complained about stability problems while processing PCR materials. Changes in parison length can cause problems such as fluctuation in bottle weight and changes in the position of the thickness profile, which lead to poor topload results.

Despite advances, blow molders still face numerous challenges in processing these materials. This article explores key challenges such as processability, odor, topload strength, migration, drop-test results, black specks, differences in color and material availability. The relevance of these challenges varies greatly depending on the regional infrastructure for material separation, collection, sorting and processing.

In this three-part collection, veteran molder and moldmaker Jim Fattori brings to bear his 40+ years of on-the-job experience and provides molders his “from the trenches” perspective on on the why, where and how of venting injection molds. Take the trial-and-error out of the molding venting process.

Migration tests with four different materials and two different bottle sizes/geometries showed that the migration in the ReCo bottles is under the legal limit and therefore safe to use in cosmetic products, both leave-on and rinse-off.

Varinia Lück earned a bachelor’s degree in chemical engineering from Universidad del Valle de Guatemala and a master’s degree in product management from the University of Oulu in Finland. After internships at Colgate-Palmolive and A. Schulman (now LyondellBasell), Lück joined W. Müller GmbH in 2018, where she serves as head of the Technology Center. She is responsible for R&D, with a particular focus on circularity (using recycled materials and biomaterials), barrier technologies, color change and foaming. Contact lab@w-mueller-gmbh.com; mullerheads.com.

Also, when comparing results of using monolayer with PCR and regrind and ReCo with PCR and regrind, improved topload was observed on the ReCo bottles (Fig. 8).

3D printing is a highly reliable, cost-effective and relatively easy-to-use production technology for small- to medium-volume applications and can rival injection molding.

The process with the least variation in gross weight, melt pressure and parison length was that of the virgin bottle. The process with the most variation was monolayer PCR material without additive. When comparing the process variation for the PCR with and without additive, it was observed that the additive reduced the process variation when using the monolayer and ReCo technologies. It was also noted that using ReCo improved process stability for both the stabilized and unstabilized material. The variation in the parison length and melt pressure of the stabilized ReCo bottle was only slightly higher than that of the virgin bottle. This means that processing PCR with three layers can improve the stability of your process when compared with processing monolayer PCR.

Core Technology Molding turned to Mold-Masters E-Multi auxiliary injection unit to help it win a job and dramatically change its process.

With each passing year, governments worldwide enact new legislation dictating the extent to which postconsumer plastics must be recycled and how much of that PCR should be incorporated into new plastic products. This regulatory landscape presents a formidable challenge for converters who must navigate the complexities of acquiring and processing these materials.

Injection molding is still the go-to technology for high-volume plastic part production, but it is characterized by significant up-front capital investment in tooling, which is also time-consuming and difficult and expensive to adapt. The technology can use several molds at the same time, which means that it is ideally suited to the mass manufacturer of parts and components cost effectively—its cost effectiveness also promoted by the fact that there is minimal wastage as material is precisely dosed to match specific mold requirements.

Also, as 3D printing is a digital process, it can be stopped post-part build or post-run and started again without punitive cost. Production volumes can be exactly aligned with demand day to day, week to week, month to month. With injection molding, once the production process is initiated, it needs to fulfill the full run immediately to remain economic, which therefore necessitates the need for warehousing—which increases the cost per part.

Join Wittmann for an engaging webinar on the transformative impact of manufacturing execution systems (MES) in the plastic injection molding industry. Discover how MES enhances production efficiency, quality control and real-time monitoring while also reducing downtime. It will explore the integration of MES with existing systems, emphasizing compliance and traceability for automotive and medical sectors. Learn about the latest advancements in IoT and AI technologies and how they drive innovation and continuous improvement in MES. Agenda: Overview of MES benefits What is MES? Definition, role and brief history Historical perspective and evolution Longevity and analytics Connectivity: importance, standards and integration Advantages of MES: efficiency, real-time data, traceability and cost savings Emerging technologies: IoT and AI in MES

Some PCR materials stand out for their excellent processability. They are typically colored white, ivory or a very light gray. In our tests with those materials, we started molding virgin HDPE into bottles and then changed to the good-quality PCR. We continued making bottles, adjusting the die gap to achieve the same bottle weight. Processing was very easy, there were no parison length variations, and the process ran stable. Some bottles had a couple of dark specks, but nothing to worry about. These materials still had a characteristic PCR smell — however, it was more the smell of a not too overpowering cleaning agent. These materials ran well even in monolayer bottles.

Across the show, sustainability ruled in new materials technology, from polyolefins and engineering resins to biobased materials.

FIG 7 – Monolayer PCR bottle (left) shows black specks, which are hidden in multilayer ReCo bottle (right). Source: W. Muller GmbH

Take a deep dive into all of the various aspects of part quoting to ensure you’ve got all the bases—as in costs—covered before preparing your customer’s quote for services.

Say “manufacturing automation” and thoughts immediately go to the shop floor and specialized production equipment, robotics and material handling systems. But there is another realm of possible automation — the front office.

After successfully introducing a combined conference for moldmakers and injection molders in 2022, Plastics Technology and MoldMaking Technology are once again joining forces for a tooling/molding two-for-one.

Some of you might think you can just color the gray PCR materials. This is possible, but the resulting color of the bottle will be nowhere near your original color, even if you increase your masterbatch use level from 4% to 8%. You will have a colored bottle, but it will still have a grayish tone and you will be spending double the money on masterbatch. Better to make a three-layer bottle and just color the outside layer. You are free to increase the amount of masterbatch in the one layer; you will still be saving money. The best thing? Your color will be either the same as your original bottle or a lot closer to it.

It is important to make an informed decision when switching to PCR. Therefore, it is helpful for you to send us your virgin and PCR material ahead of time. We can (depending on the size) help you adapt your mold to our machine, and we can sample and test the bottles for you. That way, you can pick the technology and materials that are best suited to your application.

It is important to mention that the inner layer is not to be considered a functional barrier and will not allow you to use a non-food-grade PCR material for a food-grade application. However, it can help make your product safer. If you are making a cosmetic product and are using a substance that has a concentration limit, you would not want that substance to migrate from the PCR into your product in amounts sufficient to cause you to exceed the regulatory limit.

MuCell technology gains new momentum in blow molded packaging through this partnership of a leader in physical foaming with supercritical gases and a leader in coex blow molding hardware and controls.

Depending on your chosen technology (be it DeCo, ReCo or CoEx), the required head and extruder setup can vary significantly. Furthermore, the selection of a head producer can significantly impact the outcomes of your operations.

The inner layer can help you reduce the substances that migrate into your products. The easy adjustment of the layers, depending on availability of the PCR materials, can help you to stay flexible.

Perhaps the biggest advantage of the use of 3D printing, however, is that although per part it is slow compared with injection molding, its advantages in terms of design freedom, creation of geometric complexity, and part consolidation all stimulate innovation. These factors alone may be a spur to using 3D printing for multiple smaller batch runs rather than bowing purely to the economics of using injection molding for high-volume manufacture.

FIG 4 – Three-layer ReCo technology can save masterbatch costs, avoid contact between a bottle and its contents, and improve mechanical properties of the bottle. Source: W. Muller GmbH

Let’s compare monolayer bottles (Fig. 6). Suppose your bottle weighs 70 g and you used 4% masterbatch in your virgin bottle. If you double the masterbatch level to 8% when using a gray PCR, you will be going from 2.8 g masterbatch to 5.6 g. If you make that same bottle in three layers, where the outer layer is 20% of total thickness, and you add 4% masterbatch only to that layer, you will be using only 0.56 g of masterbatch. Even if you double the amount of masterbatch in that outer layer, it is still 1.12 g, which is 60% less than you had in your virgin bottle. Imagine saving 60% in masterbatch costs and still getting a better color match than using monolayer? And you have an added benefit when using ReCo: Any black specks are covered by the outer layer (Fig. 7).

There are many multilayer blow molding technologies out there. We often hear about coextruding 11 layers or more in the film industry. But in blow molding, seven layers is the practical maximum. It is possible to make a head with more layers, but we haven’t found an application that actually needs more than that.

In this collection, which is part one of a series representing some of John’s finest work, we present you with five articles that we think you will refer to time and again as you look to solve problems, cut cycle times and improve the quality of the parts you mold.

Gifted with extraordinary technical know how and an authoritative yet plain English writing style, in this collection of articles Fattori offers his insights on a variety of molding-related topics that are bound to make your days on the production floor go a little bit better.

Ultradent's entry of its Umbrella cheek retractor took home the awards for Technical Sophistication and Achievement in Economics and Efficiency at PTXPO.

Discover how artifical intelligence is revolutionizing plastics processing. Hear from industry experts on the future impact of AI on your operations and envision a fully interconnected plant.

One test measured global migration in a monolayer PCR bottle and a ReCo PCR bottle. Even though both bottles had a global migration under 10 mg/dm² (which is the legal limit), it is important to notice that the monolayer PCR bottle had a global migration of 4 mg/dm² while the ReCo bottle had a global migration under 1 mg/dm². This was repeated with a different PCR material, and the results were similar — the monolayer PCR bottle had a global migration of 3 mg/dm² while the ReCo bottle had a global migration under 1 mg/dm².

Injection molding finds its sweet spot in large-batch production, where the requirement is for the manufacture of many thousands of identical products simultaneously. It is also best suited to robust designs based on one continuous form, and the process can produce products with superior smooth surface finish without the need for post-processing (which is typically needed with 3D printing parts).

At W. Müller, we offer, in addition to our single-layer technology (Mono), a diverse array of multilayer technologies (Fig. 2). Among these are DeCo and ReCo, comprising two (DeCo) or three (ReCo) layers of an identical material type (such as all-HDPE with layers of virgin and PCR). Additionally, our portfolio includes CoEx technologies, which entail coextrusion of different material types to achieve specific performance functions or properties, such as coextruding HDPE with EVOH or nylon for UV barrier, chemical barrier or oxygen barrier.

3D printing also promotes what can be called the consolidation of complexity. The technology can combine parts and features in one build that would otherwise have to be post-processed or assembled using conventional injection molding and allied technologies. And, printed parts can be more ergonomic and incorporate multiple parts and features that would be impossible or prohibitively expensive to achieve via the fabrication of highly complex injection molding tooling.

A Boston recycler invested in a turnkey shredding, granulation and elutriation system to expand its plastics reclaim business.

Additive technology creates air pockets in film during orientation, cutting down on the amount of resin needed while boosting opacity, mechanical properties and recyclability.

August 29-30 in Minneapolis all things injection molding and moldmaking will be happening at the Hyatt Regency — check out who’s speaking on what topics today.

There will be few manufacturing enterprises that will not either have used or are flirting with the adoption of 3D printing at some level in 2021, be it as a complementary technology to existing legacy manufacturing processes, or indeed as an alternative. Many OEMs will be using desktop 3D printers for rapid prototyping, purely to get an early reasonably accurate 3D model of their product designs, but these printers are not designed for more exacting production applications, where repeatability and accuracy / tolerance attainment are vital.

This test was also performed with the bottles made with PreZero PCR HDPE material and the Baerlocher additive. The additive also improved topload. Interestingly, the topload for the three-layer stabilized bottle was higher than the topload of the virgin bottle. That means that the ReCo technology alone already improves the topload, but material stabilization together with the ReCo technology could help reach or even improve topload results while using PCR.

While the melting process does not provide perfect mixing, this study shows that mixing is indeed initiated during melting.

While prices moved up for three of the five commodity resins, there was potential for a flat trajectory for the rest of the third quarter.

Monolayer PCR bottles in back are dull gray, while multilayer ReCo bottles in front show off coloring flexibility. Cross-sectional view shows how multilayer technologies can hide even very contaminated PCR. Source: W. Müller GmbH

Formnext Chicago is an industrial additive manufacturing expo taking place April 8-10, 2025 at McCormick Place in Chicago, Illinois. Formnext Chicago is the second in a series of Formnext events in the U.S. being produced by Mesago Messe Frankfurt, AMT – The Association For Manufacturing Technology, and Gardner Business Media (our publisher).

Plastics Technology covers technical and business Information for Plastics Processors in Injection Molding, Extrusion, Blow Molding, Plastic Additives, Compounding, Plastic Materials, and Resin Pricing. About Us

To effectively reduce masterbatch and plastic consumption, it's counterproductive to utilize a head with prolonged color and material changeover times, as each transition results in waste. Rapid changes in color and material not only bolster flexibility but also enhance overall productivity.

Join Engel in exploring the future of battery molding technology. Discover advancements in thermoplastic composites for battery housings, innovative automation solutions and the latest in large-tonnage equipment designed for e-mobility — all with a focus on cost-efficient solutions. Agenda: Learn about cutting-edge thermoplastic composites for durable, sustainable and cost-efficient battery housings Explore advanced automation concepts for efficient and scalable production See the latest large-tonnage equipment and technology innovations for e-mobility solutions

Sustainability continues to dominate new additives technology, but upping performance is also evident. Most of the new additives have been targeted to commodity resins and particularly polyolefins.

This month’s resin pricing report includes PT’s quarterly check-in on select engineering resins, including nylon 6 and 66.

3D printing finds its sweet spot in the area of prototyping and small to medium-sized production runs of geometrically complex parts and components with gaps, holes or voids. It is also the best fit for the manufacture or parts where the design will frequently evolve or where customization is required, as design changes can be accommodated even in production.

Processors with sustainability goals or mandates have a number of ways to reach their goals. Biopolymers are among them.

It seems likely that moving forward, runs of perhaps 10,000 and below will soon be the domain of 3D printing, which for such volumes will render injection molding if not redundant, increasingly irrelevant when looked at through the prism of cost and time of production. However, injection molding will never be replaced, as it will typically be the technology of choice for higher volume runs.

This Knowledge Center provides an overview of the considerations needed to understand the purchase, operation, and maintenance of a process cooling system.

3D printing requires no tooling and is agile, which facilitates quick production turnaround. With 3D printing, part cost is not connected with part complexity. As soon as complexity is introduced to an injection molded part, the requirement is for more and more expensive mold tools, which leads to an exponential increase in costs until part production is no longer viable. As 3D printing adds material, complexity of design and different incorporated shapes do not affect the amount of time that it takes to produce a part, and therefore does not lead to increased costs.

technotrans says climate protection, energy efficiency and customization will be key discussion topics at PTXPO as it displays its protemp flow 6 ultrasonic eco and the teco cs 90t 9.1 TCUs.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly