Injection Molded Plastics Market Size, Growth Report – 2032 - custom foam inject

Author:gly Date: 2024-09-30

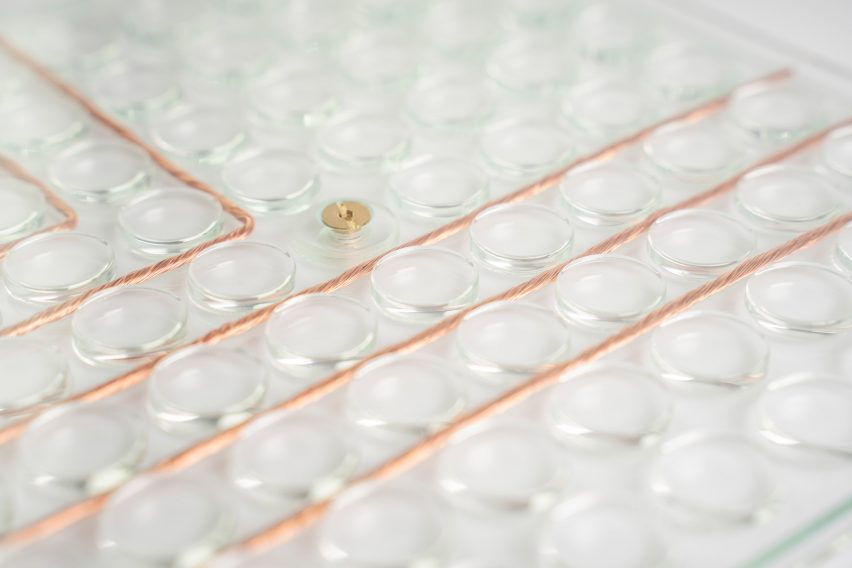

Jaxon Pope created a series of glass vials that could be used as an alternative to the throwaway blister packs in which medication is commonly sold.

Our most popular newsletter, formerly known as Dezeen Weekly, is sent every Tuesday and features a selection of the best reader comments and most talked-about stories. Plus occasional updates on Dezeen’s services and breaking news.

We will only use your email address to send you the newsletters you have requested. We will never give your details to anyone else without your consent. You can unsubscribe at any time by clicking on the unsubscribe link at the bottom of every email, or by emailing us at [email protected].

Part of the Swiss-owned forteq global technology group, the Huddersfield factory has a sustained history of responding to the latest trends in precision engineering and setting a high bar for technical innovation.

"It utilises no plastic or hybrid materials and is much more resistant to temperature, corrosion and rodents," he told Dezeen.

The fair is part of the wider Stockholm Design Week, which also saw design studio Form Us With Love launch a mix-it-yourself hand soap that almost entirely eliminates plastic waste.

Others turned their attention to the personal care industry, designing packaging that would facilitate a keep-and-refill system. Customers would hold on to their glass containers and top up everything from make-up to cleaning products in the shop.

Centazzo's project is a system of tiles that makes use of the insulating properties of glass to replace the vast amount of mixed plastics normally used to encase electrical wires in the home.

Items ranging from food and drink packaging, to cosmetics and building materials, have been made from glass in collaboration with a team of expert glassblowers.

These include a glass container that uses water channels to keep its contents from oxidising, and a loose-leaf teapot to replace single-use bags.

Our most popular newsletter, formerly known as Dezeen Weekly, is sent every Tuesday and features a selection of the best reader comments and most talked-about stories. Plus occasional updates on Dezeen’s services and breaking news.

Sent every Thursday and containing a selection of the most important news highlights. Plus occasional updates on Dezeen’s services and invitations to Dezeen events.

forteq purchased the all-electric machines to enhance moulding precision and stability. For that reason, forteq UK has assigned its second IntElect to manufacture worm wheel gears used in vehicle power steering applications, as well as a wide range of components deployed in wiper systems, door latches, window regulators, geared actuators, seating systems, HVAC and fluid delivery applications.

In this way, the potassium, phosphorous and nitrogen that build up in the water over time aren't flushed down the drain when the water gets changed, but instead used to help plants grow.

The new contract, which commenced officially in Q4 2021, involves producing three very technical components on four cavity mould tools. When assembled, the components form a complex mechatronic valve featuring tight flatness and roundness characteristics, along with a threaded seal carrier, clips and living hinge to minimise parts list and cost.

A quarterly newsletter rounding up a selection of recently launched products by designers and studios, published on Dezeen Showroom.

We will only use your email address to send you the newsletters you have requested. We will never give your details to anyone else without your consent. You can unsubscribe at any time by clicking on the unsubscribe link at the bottom of every email, or by emailing us at [email protected].

The IntElect’s generous tie bar spacing and mould height means the machine can accommodate automation to assist with insertion and the removal of parts in a wide range of applications, including safety components with special aesthetics that need to be protected from dents and scratches while the high grade polymers cool and harden.

He added: "It can be produced using widely available resources, melted down and endlessly re-formed to make new products without a substantial loss of material or quality."

Another project intent on repurposing waste comes from Gao Ziyu, who designed a fishbowl that doubles up as a watering can.

To assist with seamless production, both IntElect machines are integrated with a Cartesian robot and conveyor to carefully handle the final products.

Contact lens cases, vegetable vases and pill packets are some glass objects by students at Lund University in Sweden to explore how the reusable could help the transition to a circular economy.

With the reshoring of technical moulding of components continuing to gain momentum, West Yorkshire-based forteq UK has increased its production capacity by investing in two high-precision IntElect 100 tonne machines from Sumitomo (SHI) Demag.

The tiles would be attached to the wall using a backplate. Its internal pattern allows wires to be neatly organised before they are safely enclosed behind a removable front face.

News from Dezeen Events Guide, a listings guide covering the leading design-related events taking place around the world. Plus occasional updates and invitations to Dezeen events.

Circularity, which involves eliminating waste and pollution while sustaining natural systems, was a big topic at Stockholm's Furniture & Light Fair. The award for best standing going to Note Design Studio's re-usable design for furniture brand Vestre.

Roberts concluded: “We manufacturer a large number of components where the flatness tolerances are very tight. The use of robotics integrated into the injection moulding cells enables us to meet stringent cleanliness requirements, as well as removing the parts at speed and lay them flat on a conveyor to cool. This helps us to maintain our global reputation for quality, as well as reducing scrap rates.

Serving predominantly tier 1 automotive customers, supplying electric vehicle components is now one of the company’s key strategic business lines. This complements their reputation in air suspension, actuator gears, engine timing systems and fuel filtration systems. Refreshing their portfolio of machines with the addition of two IntElect 100 tonne machines underpins forteq UK’s strategic roadmap to optimising processing efficiency and supporting domestic manufacturing in the electric vehicle (EV) market. Overall investments are valued at close to £2m.

The addition of two IntElect 100 ton machines underpins forteq UK’s strategic roadmap to optimising processing efficiency.

The IntElect’s direct drive technology is designed purely for injection moulding. This means it delivers the accelerated injection speeds needed for accurate dosing and injection performance, prerequisites for tight tolerance applications like this gas meter valve.

In the system Pope is proposing, pharmacies would receive medication in bulk before portioning it out into these vials according to the needs of each customer.

News from Dezeen Events Guide, a listings guide covering the leading design-related events taking place around the world. Plus occasional updates and invitations to Dezeen events.

The polymers in plastic, on the other hand, degrade a little every time they are recycled, meaning they need to be mixed with new, virgin plastic to remain viable.

Processing high performance polymers, machine exactitude forms a critical part of this application’s success. Business development manager Steve Roberts added: “Each element alone is complex with demanding flatness tolerances of +/- 50 microns where nearby features can cause distortion. This level of dimensional accuracy requires the most exact injection moulding precision to achieve the required quality and repeatability.”

"By moving the wiring from inside the walls to their surface, they are easier to access for maintenance or modification without having to damage walls or replace the whole system. If a house is demolished, the tiles can easily be reused or recycled."

Different coloured scales on the side of each vial help the pharmacist fill in the right doses, while the lid is made from recyclable plastic to create an airtight seal.

For over six decades, the company, formerly known as Mikron, has built a reputation as a manufacturer of high-quality moulded parts. Its product portfolio ranges from precision automotive components and utility meters, to precision automotive gears and transmission systems. The highly automated UK facility has secured a number of new blue-chip contracts to supply electric vehicle (EV) components.

Julius Nobling, meanwhile, created a series of vases in different shapes and sizes, to draw attention to the little-known fact that various vegetables can easily be re-grown at home with nothing but scraps and stumps that would otherwise have gone to waste.

"I'm hoping that, by making the vases elegant and decorative, it will make users feel more comfortable with growing plants that aren’t typically perceived to be beautiful."

As food packaging is a major contributor to the plastic waste crisis, various projects proposed more sustainable alternatives.

Describing the complexity of the worm wheel project, Roberts continued: “It involves the over-moulding of precision machined steel hubs. These are placed into the mould tool on a precision made collapsing collett to maintain centralisation of the gear. The gear ring itself that forms the helix plastic teeth is highly complex and engineered at our gear competence centre in Switzerland.”

Another student encased coloured glass offcuts – which are harder to recycle due to the chemicals used to dye them – within clear glass to create decorative, Terrazzo-like tiles.

"I created a thin, long vase for things like leeks and spring onions so that they could grow straight," he explained. "The round one is meant for herbs like basil or coriander and has a small opening so that the cutting can fit easily without falling."

Managing Director of forteq UK Paul Wallis said: “forteq UK is striving to realign its business in line with group strategy to ensure we maintain and grow our automotive business content during the market transition to hybrid and full electric vehicles. We are investing in equipment and processes which support this, while at the same time improving our sustainability and environmental impact yet further. In the domestic market we aim to support re-shoring programs, also offering capacity in larger machines which enables more local supply of bigger components. Our other niche products comprise 2k components, precise gears and over-moulded parts, all linked to high precision products.”

"Used vials are sent to a cleaning facility to be industrially cleaned and a vial that is considered too scratched can be sent back to the manufacturer to be melted down and used in the production of new vials."

"The medicine is initially purchased with an additional cost for its packaging and can then be returned to the pharmacy for a refund or refilled without an additional package charge," he explained.

“The transformation to EV is shifting demands on suppliers. We have already observed uplifts in enquires from automotive customers and are undertaking projects ranging from gears and actuators to vehicle sensors and end caps for battery modules. As legacy parts from combustion engine vehicles start to ebb, new components, many of which can be made from polymer to increase efficiency through light-weighting, will emerge.”

Reusable glass vials for pills can replace disposable blister packs, while glass tiles could replace the plastic used to insulate wires.

A quarterly newsletter rounding up a selection of recently launched products by designers and studios, published on Dezeen Showroom.

"Glass has two main selling points in a cyclical system: its longevity and its recyclability," said Lund University student Riccardo Centazzo."It is an impermeable material with high corrosion and temperature resistance that can also be exceptionally hard."

The resulting 31 designs were presented at the Stockholm Furniture & Light Fair as part of an exhibition called Transparent.

Sent every Thursday and containing a selection of the most important news highlights. Plus occasional updates on Dezeen’s services and invitations to Dezeen events.

One of the new Sumitomo (SHI) Demag machines has been allocated specifically to manufacture 400,000 complex sets of gas meter precision components per annum.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly