Improve Production Rates Via Screw Design — Barrier vs. General Purpose vs.

Author:gly Date: 2024-09-30

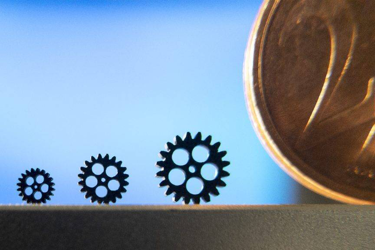

The medical device industry demands increasingly smaller products with precise, micron-level tolerances, necessitating partnerships with micro molding experts like Accumold. These experts provide the precision, repeatability, and zero failure rates crucial for safety-critical applications.

The Corporate and Other Activities segment of the Rapid Injection Molding Market includes the overarching business operations, administrative functions, and ancillary services that support core business activities. This segment typically involves strategic management, financial oversight, legal affairs, and other essential administrative tasks that ensure smooth business operations.

– Financial Health: Assessed through financial statements and reports, highlighting profitability, cost management, and investment efficiency.

– Strategic Impact: Analyzes how corporate decisions and administrative activities influence long-term business strategy and market positioning.

Micro molding for medical device OEMs requires years of expertise and the right business culture, personnel, and equipment to ensure project success. Micro molders handle low, medium, and high volume runs with various materials, requiring different validation levels. They must also expertly manage the handling, storage, and processing of costly, sensitive materials used in critical implantable applications.

The Distribution segment within the Rapid Injection Molding Market focuses on the logistics, supply chain management, and distribution strategies used to deliver products and services to end-users. This segment includes various channels such as wholesalers, retailers, and direct-to-consumer models, ensuring that products reach the market efficiently and effectively.

Do You Have Any Query Or Specific Requirement? Ask to Our Industry Expert @ https://www.orbisresearch.com/contacts/enquiry-before-buying/7269310

Accumold invites all medical OEMs at MEDevice Boston to visit and discuss how micro molding with Accumold can drive the manufacture of innovative, timely, and cost-effective medical devices.

The Rapid Injection Molding Market encompasses a diverse range of sectors and activities under the Rapid Injection Molding designation. This market includes various business segments that contribute to its overall landscape. The key segments are analyzed to understand their roles, performance, and impact on the market.

Brett Saddoris, Accumold’s Technical Marketing Manager says, “We are excited to be at MEDevice Boston, and we are proud to have collaborated with numerous leading medical device manufacturers globally, working strategically with each to ensure the most efficient product development process. The key to success lies in medical device OEMs viewing their micro molder not just as a job shop but as a partner from the earliest stages of the design-to-market process to avoid costly errors. Manufacturing micro medical plastic products necessitates a genuine partnership between OEMs and micro molding specialists, distinct from traditional OEM/supplier relationships. In micro manufacturing, the most critical issues often arise during the design and prototyping stages, including material selection and packaging considerations. A true partnership ensures faster time-to-market with more efficient and cost-effective products.”

Conventional Rapid Injection Molding Structural Foam Molding Gas-assisted Injection Molding Overmolding and Insert Molding Others

Hector Costello Senior Manager – Client Engagements 4144N Central Expressway, Suite 600, Dallas, Phone: +1 (972)-591-8191, Email: sales@orbisresearch.com

– Logistics Efficiency: Evaluation of supply chain effectiveness, including inventory management, transportation, and warehousing. – Market Reach: Analysis of distribution network breadth and the ability to penetrate different geographic regions. – Customer Satisfaction: Measures of service quality, delivery timeliness, and overall customer experience. – Cost Management: Review of distribution-related costs and their impact on profitability.

– Operational Efficiency: Measures how effectively the administrative and support functions contribute to overall business operations.

At the MEDevice show in Boston on September 25-26, Accumold will showcase a variety of innovative medical parts and components at booth 815. These products reflect the company’s extensive experience and deep understanding of design for micro manufacturing (DfMM). Accumold stands out due to its vertical integration, enabling it to serve as a comprehensive partner in developing and manufacturing medical devices. Their offerings include design and material support, micro tool fabrication, proprietary micro molding services, advanced metrology, assembly, and automation. This integration streamlines the medical product development process, optimizing timeliness, innovation, cost, and accuracy.

This research report provides an in-depth analysis of the Rapid Injection Molding Market, focusing on the performance and dynamics of key business segments: Corporate and Other Activities and Distribution. Each segment is evaluated for its operational effectiveness, financial health, strategic impact, and logistical efficiency, offering a comprehensive view of the market’s structure and performance.

Saddoris continues, “Medical device OEMs are under pressure to maintain profitability despite decreasing prices, which necessitates the development of innovative products that meet increasingly stringent end-user demands. There will be a growing need for versatile devices that leverage the potential of 'smart' diagnostics and treatment through the proliferation of 'big data,' as well as cost-effective alternatives to traditionally expensive diagnostic and therapeutic devices. Micro molding is the preferred solution for many medical device OEMs to meet these rigorous manufacturing requirements.”

Proto Labs Xcentric Mold & Engineering ICOMold Protolabs RapidDirect Star Rapid DLUX 3D Printing Jabil Uidea Rapid Prototype Bay Area Rapid Manufacturing (BARM) Firstcut by Proto Labs Indotech Fast Radius Fathom Midwest Mold Services Quickparts PTI Engineered Plastics Stratasys Direct Manufacturing Prismier BTL Prototypes Premier Die Casting Kintec APT Mold Manufacturing Product Development Solutions Silicon Valley Manufacturing

Accumold’s micro molding process enables the production of tiny, complex, and feature-rich components efficiently, cost-effectively, and in large volumes. The expert use of micro molding technologies provides medical device OEMs with a competitive edge, driving both product innovation and profitability. High-quality parts with precise dimensional accuracy are crucial for sensitive medical applications, including specialized devices for cancer treatment and diagnosis, small molded catheter tips, micro-needles, small surgical instruments, dental implants, infection control devices, and staples, among others.

Medical Devices Automotive Industry Aerospace Industry Consumer Electronics Industrial Equipment Others

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly