HDPE Market Soars in Europe and US Amid Supply Shortages and Surging Demand - hi

Author:gly Date: 2024-09-30

Li, K., Yan, S., Pan, W. & Zhao, G. Warpage optimization of fiber-reinforced composite injection molding by combining back propagation neural network and genetic algorithm. Int. J. Adv. Manuf. Technol. 90, 963–970. https://doi.org/10.1007/s00170-016-9409-3 (2017).

Analysis of residual stresses in the second direction: Range analysis of residual stresses in the second direction in Table 3. The analysis results are shown in Table 7.

The cylinder liner mainly acts as a barrier to hydrogen. This simulation uses ammonium polyphosphate (PA6). The main performance indicators are shown in Table 1.

Meanwhile the Irish injection moulding sector races forward on all fronts: The expansion is largely in line with the Republic’s general economic expansion (first in Europe), unhindered by the presence of brown or legacy industrial site, and also largely powered by the growth demand from medical OEM throughout that country. (About half of Ireland’s injection moulding output goes to medical and healthcare suppliers.)

Analysis of volume shrinkage results are shown in Table 3 and the analysis results are shown in Table 5, where the influence order of the process parameters on the volume shrinkage rate is: holding time > melt temperature > mold temperature > holding pressure > cooling time.

k1, k2, k3 and k4 donate the average of the sum of each factor index at four levels, and the difference is R. Through the analysis of the warping process range, a better combination of process parameters A4B2C3D3E3 can be obtained. When the melt temperature reaches 270 °C, the mold temperature reaches 80 °C, the holding pressure is 55 MPa, the holding time is 20 s, and the cooling time is 18 s. The optimum combination was not in the test times, the optimized molding process parameters were entered into Moldflow software for analysis and verification. The final result is shown in Fig. 4, with a warping of 0.5185 mm.

For its part, the equipment supplier must be willing to embrace the challenge of designing, manufacturing and servicing all of this connected equipment in order to add value for the moulder and to reduce moulding production cost.

Back then, Industry 4.0 had yet to fully emerge but terms such as kaizen, kan ban, JIT, various forms of 6 Sigma and CI (Continuous Improvement) and various metrics such as OTIF and OEE were all becoming well-known and practiced - part of the trickle down from leading global manufacturing practice. The sciences of metrology and a revolution in QA technology and methods were also becoming incorporated as standard in many moulding enterprises.

Walsh says that ‘having carried over fifty of these medical validations we have found that the repeatability of the new Wittmann Battenfeld Machines are so good that any variation whatsoever on part dimension can be attributed to operator measuring error rather than machine variation.’

The minimum characteristic warping value is set to Y1, and SNR is set to η1. The minimum volume shrinkage eigenvalue is set to Y2, the corresponding SNR value is η2, the minimum first residual stress is set to Y3, SNR is set to η3, the minimum second residual stress is set to Y4, and SNR is set to η4. The total SNR is as follows:

Xu, G. & Yang, Z. Multiobjective optimization of process parameters for plastic injection molding via soft computing and grey correlation analysis. Int. J. Adv. Manuf. Technol. 78(1–4), 525–536 (2015).

"One phone call: That’s all I ever need or want to make if I want to explore all the possibilities in our moulding system. I will typically call up and ask - “Can the cell do this?” – to which the answer is typically “Yes” or else be provided with options. In this way, we are supported to get on with our creativity, efficiency and sales."

The energy data can also be aggregated into logical units in order to make evaluation even more straightforward. The program runs as a web application, both as an optional extension to Wittmann’s MES software and as a stand-alone program. The energy costs per machine can be apportioned to the individual production cycle of the IMM or even for specific injection moulded parts and jobs – thus providing production and environmental transparency that is an increasing requirement for today’s circular economy.

Wang, G., Wang, G., & Yang, G. Study on automotive back door panel injection molding process simulation and process parameter optimization. Adv. Mater. Sci. Eng. https://doi.org/10.1155/2021/9996423 (2021).

The SNR and ANOVA were carried out. In order to minimize the comprehensive evaluation index value of the bottle liner, the SNR was analyzed. The optimum technological parameters were obtained as follows: A2B4C4E4E4. Under this technological parameter, the optimum warpage was 0.4892 mm, the volume shrinkage was 12.31%, the first direction residual stress was 98.13 MPa, and the second direction residual stress was 108.1 MPa. ANOVA was used to determine the significance of each factor in experimental research. After analysis, it was found that the melt temperature has the greatest influence on the comprehensive index, accounting for about 62.15%, followed by a pressure holding time and cooling time.

Orthogonal experimental optimization technology, an experimental method to study multiple factors and levels, employs different orthogonal arrays to minimize the number of experiments, thereby reducing the time and cost25. The purpose of the experimental study must be established before designing orthogonal experiments. The experimental measurement indicators are developed in accordance with the objectives of the experimental study to determine the influencing factors of the experiment.

Li, C.-L. Design of flip-chip injection mold for chassis top cover based on CAE technology. Plastics 49(04), 50–54 (2020).

The above analysis showed that mean and range processing is an effective method to analyze and optimize single factors. However, these methods cannot be used simultaneously to optimize multiple objectives. In order to optimize the multi-objective data and carry out a comprehensive analysis to achieve the goal of this study, we introduced grey correlation analysis27.

Today’s moulders are therefore increasingly appreciative of a ‘plug and produce’ system, especially when setting up shop for a new client. Those suppliers who can supply and service a moulding system solution are increasingly in favour. All moulding aspects are covered – including machine production, automation, conveying, temperature control, materials drying and feed, granulation, as well as connectivity and 4.0 control.

According to the injection molding results shown in Table 7, the influence order of the process parameters on the residual stress in the second direction is:holding time > mold temperature > melt temperature > holding pressure > cooling time.

Md Yusof, M. & Abu Mansor, M. S. Alternative method to determine parting direction automatically for generating core and cavity of two-plate mold using B-rep of visibility map. Int. J. Adv. Manuf. Technol. 96, 3109–3126 (2018).

Xu, Y. et al. Optimization of injection molding process parameters to improve the mechanical performance of polymer product against impact. Int. J. Adv. Manuf. Technol. 76(9–12), 2199–2208 (2017).

Li, J., Zhao, C., Jia, F. et al. Optimization of injection molding process parameters for the lining of IV hydrogen storage cylinder. Sci Rep 13, 665 (2023). https://doi.org/10.1038/s41598-023-27848-1

Lasn, K. & Echtermeyer, A. Safety approach for composite pressure vessels for roadtransport of hydrogen. Part 1 Acceptable probability of failure and hydrogend mass. Int. J. Hydrogen Energy 39(26), 1413e241 (2014).

According to the injection molding results shown in Table 9, the influence degree of the process parameters on the grey correlation data is: holding time > mold temperature > cooling time > holding pressure > melt temperature.

All data generated or analyzed during this study are included in this published article and its supplementary information files.

Come the present day, it’s clear that any moulders that sought to avoid the menu of the 90s – leading up to the present day - have probably perished. The stats and databases bear this out. The UK’s contract moulding population now stands at about 880 businesses (Ireland’s now approaches the 250 mark) and its remaining cohort now faces a series of new challenges:

By analyzing the residual stress process range in the second direction, a better combination of process parameters A3B2C2D3E2 can be obtained. When the melt temperature reaches 260 °C, the die temperature reaches 80 °C, the holding pressure is 50 MPa, the holding time is 20 s, and the cooling time is 13 s. The optimum combination is not in the test times, the optimized molding process parameters are input into Moldflow software for analysis and verification. The final result is shown in Fig. 7. The residual stress in the second direction is 136.8 MPa.

An important parameter considered in the design and manufacture of plastic parts is the parting surface (PS), which depends on the complexity of the parts and directly affects the design of the mold. One of the most time-consuming activities in mold design is to determine the parting surface14, which is mostly due to the fact that a variety of component geometry and pouring process-related elements must be taken into account when determining the parting surface. A reasonable parting surface helps simplify the mold structure and reduce costs15,16.

Dicheng, F. Design of injection mold for automotive cable connector based on CAD/CAE. Plast. Technol. 48(06), 102–108 (2020).

Injection molding (IM) is a popular polymer processing technology for the manufacture of plastic products with complex shapes, high precision and low cost, resulting in products with high quality and good dimensional tolerances5,6. Mode design and process parameters can improve the quality of injection molded parts. One of the main tasks of mold design is gate design7. The gate is the first orifice where the material is injected into the cavity. It has been demonstrated that an appropriate gate size and runner aid in the quick injection of molten plastic into the cavity, enhance the product's mechanical characteristics and aesthetics, and lessen warping and residual stresses in injection-molded components8,9. Another factor in the design of the mold is the number of gates. Setting two gates on both sides of the product as opposed to only one on one side will enhance the turbulence of molten plastic. Another significant element influencing the quality of injection-molded products is the gate position in the mold design. Injection molded components can solidify faster and with fewer flaws if the gate is placed properly10,11,12,13.

Kramschuster, A. et al. Effect of processing conditions on shrinkage and warpage and morphology of injection moulded parts using microcellular injection moulding. Plast. Rubber Compos. 35(5), 198–209 (2006).

Zhao, P. et al. A Nondestructive online method for monitoring the injection molding process by collecting and analyzing machine running data. Int. J. Adv. Manuf. Technol. 72, 765–777 (2014).

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.

Some twenty years ago the UK’s contract injection moulding numbers of the UK could be generously counted at some 1050 companies – and with hindsight, quite possibly the crest of a wave.

Liu, X. Design of complex side core-pulling injection mold for automotive headlight housing. Eng. Plast. Appl. 49(11), 99–103+108 (2021).

The components that make up an injection mold are referred to as the molding parts, and typically include the core, cavity, different molding rods, and molding inserts. Forming parts can be divided into installation parts and working parts. To produce plastic components, working parts come into close contact with the plastic parts33. In order to lower the cost of the die, it is advantageous to process and manufacture the structural design of die components in a way that is both convenient and easy to acquire qualified parts34.

The purpose of ANOVA is to investigate which factors significantly affect performance characteristics. The ratio of deviation square sum and total deviation square sum for each factor in variance analysis reflects the influence of process parameters on test indexes. In this paper, \(\overline{{I_{{\text{j}}} }}\) is the average SNR of a certain experimental factor at a certain level, and the average signal-to-noise ratio of all levels of all experimental factors are taken.

The percentage contribution of each factor to the SST sum of squares can be used to assess the importance of process parameter variations on the performance characteristics. In addition, the F value shown in Table 12 can also be used to determine which factors have significant effects on performance characteristics. Typically, changes in deterministic factors have a significant effect on performance characteristics when the F-values are large.

The Covid emergency brought plenty of those: Dick Walsh, founder and owner of Plymouth-based injection moulder TML recalls that "the most time-consuming part of medical verifications consists of the capability studies: These involves measuring various numbers of components that have been produced during three x three hour production runs. Normally we measure up to 125 parts on key dimensions with an acceptance criteria of CPK 1.66."

At this time, a set of re-optimized process parameters can be obtained. The optimized combination parameters are expressed as A4B2C2D3E2. When the melt temperature reaches 270 °C, the die temperature reaches 80 °C, the packing pressure is 55 MPa, the packing time is 20 s, and the cooling time is 13 s. The simulation results of the process parameters in Moldflow software are shown in Figs. 8, 9, 10 and 11. The warpage is 0.5041 mm, the volume shrinkage is 12.4%, the residual stress in the first direction is 97.88 MPa, and the residual stress in the second direction is 114.1 MPa.

Song, Z. et al. Optimization and prediction of volume shrinkage and warpage of injection-molded thin-walled parts based on neural network. Int. J. Adv. Manuf. Technol. 109, 755–769 (2020).

"And that applies in three dimensions,’ he adds.’ A reduced machine height can literally give you the clearance to get through some factory doors, and a shortened length and depth usually means that our machines are creating space for the customer – not taking it away."

Ozcelik, B. Optimization of injection parameters for mechanical properties of specimens with weld line of polypropylene using Taguchi method. Int. Commun. Heat Mass Transf 38(8), 1067–1072 (2011).

Sateesh, N., Reddy, S. D., Kumar, G. P. & Subbiah, R. Optimization of injection moulding process in manufacturing the top cap of water meter. Mater. Today Proc. 18, 4556–4565 (2019).

Hydrogen is an important renewable and sustainable energy source with the advantages of zero pollution, a high energy conversion rate and an abundance of resources. The wide application of hydrogen energy requires solving the problems of hydrogen production, storage and transportation. Hydrogen storage technology is the key to hydrogen utilization1. Among them, a hydrogen storage cylinder is the most commonly used way of hydrogen storage, consisting of a lining and a composite winding layer. At present, the cylinders can be divided into type III aluminum liner and type IV polymer liner2. High density polyethylene (HDPE), polyamide (PA6), or PET(Polyethylene terephthalate) are the primary materials utilized to create type IV cylinder linings3. In general, injection molding is one of the methods of lining molding. The plastic molding technology, namely, the combination of metal head and resin lining molding, is used to produce lining through injection molding4.

Different from the orthogonal experiments, Taguchi algorithm introduces the concept of SNR on the basis of orthogonal experiments. In Taguchi algorithm, the index of measuring test results is no longer a certain analysis data. Instead, the analysis is converted into an SNR28.

All this by way of a preamble to note that the UK’s injection moulding sector has been continually becoming ever more efficient, simply in order to survive.

Over the past thirty years, Wittmann has also invested energy and innovation in ensuring that all of its machines are leaders in low energy consumption. Energy cost is a critical issue for populations today; particularly for manufacturers and all the more so since the Russia/Ukraine war began.

Moving staff and equipment out of the confines of one factory and into another is easier said than done. Indeed, it very rarely happens. Instead, the business has to somehow achieve more within the same physical constraints. Anything to help that process therefore – smaller, more compact technology - will automatically go to the front of possible procurement.

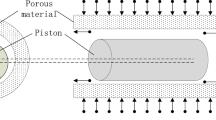

Parting surface of cylinder liner. 1. Positioning ring 2. Fixed template floor 3. Fixed template 4. Dynamic die 5 PS surface 6. guide post.

\(\xi_{{\text{i}}} (k)\) represents the gray relational coefficients, \(\Delta_{{0{\text{i}}}} (k)\) represents the sequence differences between corresponding positions in sequence \(x_{0} (k)\) and subsequence \(x_{{\text{i}}} (k)\), \(\xi\) represents the identification coefficient (generally, 0.5).

Over the past two decades therefore – and principally through its energy-reduction expertise - Wittmann has been staying ahead of the sustainable curve. Solar powered injection moulding machines and bicycle powered robots have provided the ‘wow factor’ at important trade shows. More importantly, year-on-year best reduction in energy equipment ratings, and diagnostic tools such as IMAGOxt have been making a practical and sustainable differences for its customers.

To minimize the comprehensive evaluation index value of cylinder liner plastic parts, this paper uses the SNR function of the small characteristic to calculate its SNR. The larger the SNR is, the smaller the target value is, and the better the quality performance is. SNR is calculated according to the following formula:

Over the past five years WIBA UK has found that for many of its moulding customers ‘doing more with less’ means accomplishing the difficult trick of expanding the business within the fixed constraints of an existing site. And that mastery often comes down to simple physical factors.

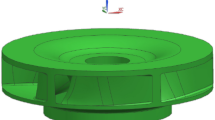

The hydrogen storage cylinder lining was taken as the research object. The injection model of the cylinder liner was developed employing 3D software, a two-cavity injection molding system was built, and Moldflow was utilized for analysis to determine the best combination of injection molding process parameters. The effects of injection process parameters (melt temperature, mold temperature, holding pressure, holding time and cooling time) on the evaluation index were analyzed by orthogonal experiment L16(45). The prediction data of IV hydrogen storage cylinder lining under different parameters were obtained by the range analysis method. The multi-objective optimization problem of injection molding process was transformed into a single-objective optimization problem by using the grey correlation analysis method. The optimal parameters such as melt temperature 270 °C, mold temperature 80 °C, packing pressure 55 MPa, packing time 20 s and cooling time 13 s were obtained. Taguchi method was adopted to obtain SNR (signal-to-noise ratio), while range and variance methods were used for analysis. The results showed that warpage was 0.4892 mm, the volume shrinkage was 12.31%, the residual stress in the first direction was 98.13 MPa, and the residual stress in the second direction was 108.1 MPa. The comprehensive index was simultaneously most impacted by the melt temperature.

\({\text{x}}_{{\text{i}}}^{*} (k)\) represents the gray relational values, max \({\text{x}}_{{\text{i}}}^{*} (k)\) and min \({\text{x}}_{{\text{i}}}^{*} (k)\) respectively represent the largest and the smallest values in the \({\text{x}}_{{\text{i}}}^{*} (k)\) sequence.

Thank you for visiting nature.com. You are using a browser version with limited support for CSS. To obtain the best experience, we recommend you use a more up to date browser (or turn off compatibility mode in Internet Explorer). In the meantime, to ensure continued support, we are displaying the site without styles and JavaScript.

Toe, C. Shrinkage behavior and optimization of injection molded parts studied by the Taguchi method. Polym. Eng. Sci. 41(5), 703–711 (2001).

Hassan, H., Regnier, N. & Defaye, G. A 3D study on the effect of gate location on the cooling of polymer by injection molding. Int. J. Heat Fluid Flow 30, 1218–1229 (2009).

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

Through orthogonal experiments, the effects of molding parameters on volume shrinkage, warpage, first residual stress and second residual stress of cylinder liner were studied, and the optimal combination of molding parameters corresponding to four groups of evaluation indexes was obtained. The experimental results of four evaluation indexes under the combination of 16 groups of different process parameters are shown in Table 3.

The influence of process parameters on the evaluation index was further optimized by grey correlation analysis and Taguchi algorithm based on SNR.

Xianbing, C., Yifei, C. & Yuanji, S. Design and CAE optimization analysis of injection mold for set-top box pouring into the same mold and different cavity. Eng. Plast. Appl. 49(08), 87–92 (2021).

According to the structure and process requirements of hydrogen storage cylinder liners, the cylinder liner forming mold was designed. The mold had two cavities, and the core was extracted using a hydraulic auxiliary method.

Lizhen, I. et al. Optimization of molding process parameters of automobile gear lever based on orthogonal test. China Plast. 33(7), 50–56 (2019).

J.L and C.J.Z designed this study. J.L. did most of the laboratory analysis and wrote the first draft of the paper. S.H.M contributed to data interpretation and manuscript revision. F.L.J and S.Y.L participated in the experimental analysis and sample collection. J.G.L put forward constructive suggestions.

The analysis in Table 12 shows that melt temperature is the most important factor affecting the four analyzed parameters. Compared with the other four factors, the influence of melt temperature on the four factors is 62.15%, accounting for the leading role, while the influence of holding pressure on the four factors is 4.15% (Supplementary file). The effect of mold temperature, holding time and cooling time on the four factors are 6.40%, 12.82% and 12.48%, respectively. The order of four factors is melt temperature > holding time > cooling time > mold temperature > holding pressure.

For simultaneous analysis of four evaluation indicators, residual stress in the first direction and residual stress in the second direction, the range analysis of grey correlation analysis was carried out. The best combination of process parameters was discovered when the process parameters were set to A4B2C2D3E2 (when the melt temperature reaches 270 °C, the die temperature reaches 80 °C, the packing pressure is 55 MPa, the packing time is 20 s, and the cooling time is 13 s) The optimal warpage, volume shrinkage, residual stresses in the first direction and residual stresses in the second direction were 0.5041 mm, 12.4%, 97.88 MPa and 114.1 MPa, respectively.

Chen, S.-C. et al. Effect of cavity surface coating on mold temperature variation and the quality of injection molded parts. Int. Commun. Heat Mass Transf. 36(10), 1030–1035 (2000).

This research is supported by the National Natural Science Foundation of China (Grant number 52075361), the Major Science and Technology Project of Shanxi Province (Grant number 20201102003) and the Key Research and Development Projects in Shanxi province (Grant number 201903D421030).

Hou, B. et al. A hybrid hint-based and fuzzy comprehensive evaluation method for optimal parting curve generation in injection mold design. Int. J. Adv. Manuf. Technol. 112, 2133–2148 (2021).

It goes without saying that injection moulding today is a very tough business. Whether today’s fresh challenges will further thin out the general population is anybody’s guess. It may be that perhaps a corner has been turned. In any event, partnering with the right suppliers is a critical factor in planning for future success.

For Mark Fellowes, operations director with Malvern-based Talisman Plastics the advantage in single source supply includes the peace-of-mind and equipment synergy provided by one manufacturer. More importantly, the move opens up opportunities in aftersales service and partnership:

Cylinder liner mold assembly drawing. 1. Floor 2. Push rod fixing plate 3. Push rod 4. Push rod 5. Dynamic die fixing plate 6. Dynamic die 7. Fixed template 8. Guide sleeve 9. Positioning ring 10. Gate sleeve 11. Screw 12. Fixed template floor 13. Type cavity inserts 14. Dynamic template 15. Push rod 16. Recoil pin 17. Spring 18. Floor rod.

"We’re quite happy to share that we’ve won machinery orders in competition simply because our moulding machines are that much more compact than others," said Dan Williams, joint managing director of Wittmann Battenfeld UK.

The SNR of small characteristics is a monotonically decreasing function, and the larger the value, the better the SNR. Therefore, in the average analysis of hydrogen storage cylinder liners, the minimum value of the total SNR should be obtained at the maximum SNR. It can be seen from the table that the optimal process parameters corresponding to the total SNR range analysis are A2B4C4E4E4, that is, the corresponding process parameters are: melt temperature is 250 °C, mold temperature is 100 °C, holding pressure is 65 MPa, holding time is 25 s, cooling time is 23 s. The simulation results of the process parameters are shown in Figs. 12, 13, 14 and 15. The warpage is 0.4892 mm, the volume shrinkage is 12.31%, the residual stress in the first direction is 98.13 MPa, and the residual stress in the second direction is 108.1 MPa.

"The small footprint of the SmartPower was therefore ideal for us. It is a full one metre shorter and also slightly narrower than any alternative supplier. And again, the robot and machine together as a single package with quick delivery was very helpful."

In addition to all these factors the past twenty years have brought another issue sharply into focus – the world’s emerging circular economy and the need for sustainable manufacturing practices within it.

The grey correlation degree of a comprehensive evaluation of hydrogen storage cylinders is derived from formula (1) to formula (4). At this time, the four factors multi-objective evaluation index problem can be transformed into a single objective evaluation index problem. The results are shown in Table 8. The grey correlation data were processed by the range and mean analysis, and the results are shown in Table 9.

Based on its long-standing energy experience the Wittmann strategy is simple: "Either your inefficient machinery costs you money every day," said Williams "or else it makes you money and helps pay off your investment earlier."

Joint WIBA UK MD, Tracy Cadman said that "it doesn’t matter what IMM machinery or peripherals you are running in your moulding shop, WIBA UK offers you the IMAGOxt analysis package free of charge. We make sure to play our part in providing energy solutions that are based on real time data and science."

In order to visualize the influence of various factors on warpage deformation, a range analysis was introduced. The range is the difference between the maximum and minimum values of the average value of each parameter test result at different levels35. The larger the range value, the greater the impact of the coefficient on the index and the higher the impact on evaluation indicators.

These firms had already seen out a number of economic contractions and hard times and were by no means inefficient – getting on, for example, with issues such as Investors in People, the BS and ISO standards and starting to deliver the all-important KPIs (Key Performance Indicators).

According to the injection molding results shown in Table 6, the influence order of the process parameters on the residual stress in the first direction is: melt temperature > cooling time > mold temperature > holding pressure > holding time.

Analysis of warpage results: The warpage test data in Table 3 were analyzed by the range analysis method, and the analysis results are shown in Table 4.

According to Table 10, the average SNR and range of each process parameter are calculated, and the results are shown in Table 11.

Kent says that injection moulders should know – like it or not - that "the sustainable agenda is unavoidable and urgent: On the upside if you satisfy sustainable values you will increasingly be on the right side of winning new business, especially internationally and especially also with OEMs, large purchasers and governments. On the downside if you have no sustainable credentials your business will simply shrink and fade. It’s also not a case of if – but when."

The reasonable setting of the feeding system affects the quality of the parts. Selecting the proper gate number and location may not only increase forming efficiency but also guarantee the quality of the components. Considering the shape of the lining structure and to ensure a smooth surface shape, after a comprehensive analysis, the end of the barrel section away from the metal head was chosen as the pouring position. Considering the parting surface and pouring position, the submerged gate pouring was selected. When the mold was opened, the gate can be automatically separated from the plastic part under the tension of the template. Figure 2 shows a mold with a two-cavity hydrogen storage cylinder lining structure and gate system, taking into account the injection molding machine's current structure and lining structure.

Xie, P. et al. Effect of gate size on the melt filling behavior and residual stress of injection molded parts. Mater. Des. 53, 366–372 (2014).

Moulders today also have less time to spend and ‘old school’ engineering skill sets are increasingly hard to find – e.g. those that involve mixing, matching and fine-tuning disparate pieces of equipment from various suppliers. Those days are perhaps nearly over– both for suppliers and buyers.

Almeida, F. D., Sousa, V. F. C., Silva, F. J. G., Campilho, R. D. S. G. & Ferreira, L. P. Development of a novel design strategy for moving mechanisms used in multi-material plastic injection molds. Appl. Sci. 11(24), 11805 (2021).

St Austell-based Polymermedics is a case in point. "For a customer such as ourselves - in a legacy factory – started in 1979 - and with limited space - it’s a relatively simple issue. Basically, we need to source the smallest possible machine footprint – but with the largest possible platen and tooling area," said Polymermedics operations director, Neil Skyba.

Hirscher, M. et al. Materials for hydrogen-based energy storage e past, recent progress and future outlook. J. Alloys Compd. 827, 153548 (2020).

Analysis of residual stresses in the first direction is indicated in Table 3 and the analysis results are shown in Table 6.

But best of all is the fact that – despite the overall unit reductions - Wittmann has also increased the size of the mould platen area; meaning that the machines punch considerably above their factory footprint size - whether classed as 80t, 120t, 240t, 300t, 700t or any other locking force.

The PS is the part that can be contacted when the moving mold and the fixed mold are closed, and the parting surface is where the plastic part is removed from the mold. The design of PS directly affects the product quality, mold structure and the difficulty of operation, and is one of the key factors for the success of mold design. When determining the parting surface, the location of the plastic part in the mold, the design of the cavity gating system, the structural manufacturability of the plastic part, the mold fabrication, venting and the operation process must be considered in conjunction with the design features of the hydrogen storage cylinder liner. After considering the above characteristics, the lining parting surface diagram was obtained, as shown in Fig. 131,32.

Researchers have used a variety of optimization techniques in injection molding over the last few decades to lower various defect rates. Researchers used the experimental design (DOE) approach to perform a pilot thorough investigation of the injection molding process since warpage and shrinkage are two major injection molding defects. For warpage and shrinkage prediction, the neural network method is used to significantly reduce the defect rate21,22. The neural network has become a powerful and practical method for modeling highly complex nonlinear systems. In order to determine the optimum level of design parameters, a genetic algorithm is applied to the optimization of injection molding parameters of plastic parts23,24. Taguchi, another method for improving the quality of injection molded parts, is a robust parameter design technology, and shrinkage optimization plays a major role in determining the final size of injection molded parts. This method also determines the optimal level of each process parameter to reduce shrinkage and warpage in thin-walled products25,26. ANOVA (analysis of variance) and SNR (signal-to-noise ratio) are used for data analysis to determine the importance of factors, provide the initial optimal combination of process parameters, and obtain the contribution percentage of quantitative factors27,28. Grey correlation analysis is usually used in data processing of Taguchi orthogonal test to transform a multi-objective problem into a single-objective problem, which is beneficial for analyzing comprehensive data from tests29,30.

The comparison of ANOVA and ANOVA shows that the degree of influence of each factor is consistent, but ANOVA can more intuitively see the influence of each factor on the index.

Through the analysis of the first direction residual stress process range, better process parameters combinations A4B2C1D3E4 can be obtained. When the melt temperature reaches 270 °C, the mold temperature reaches 80 °C, the holding pressure is 50 MPa, the holding time is 20 s, and the cooling time is 23 s. The optimum combination is not in the test times, the optimized molding process parameters are input into Moldflow software for analysis and verification. The final result is shown in Fig. 6. The residual stress in the first direction is 98.43 MPa.

Pomerleau, J. & Sanschagrin, B. Injection molding shrinkage of PP: experimental progress. Polym. Eng. Sci. 46(9), 1275–1283 (2006).

In this paper, the hydrogen storage cylinder liner structure needs to be molded by injection molding on the base of the metal head. Therefore, the core, cavity and ejection mechanisms of the hydrogen storage container liner injection model were designed, and the mold parts were established by 3D software. The mold design required not only the above mentioned parts but also the mold frame, gating system, cooling system, ejection mechanisms and exhaust system be supported. The three-plate mold frame and double cavity mold were used, and the latent gate was used in the gating system. Cooling channels were provided in the cavities and cores. The injection parts were ejected by a hydraulic ejector bar. A large amount of gas generated in the molding process will be carried away through the gap between the inserts. The final two-dimensional engineering diagram is shown in Fig. 3.

Shen, Y.-K. et al. Analysis for optimal gate design of thin-walled injection molding. Int. Commun. Heat Mass Transf. 35, 728–734 (2008).

Ozcelik, B., Kuram, E. & Topal, M. M. Investigation the effects of obstaclegeometries and injection molding parameters on weld line strength usingexperimental and finite element methods in plastic injection molding. Int. Commun. Heat Mass Transf. 39, 275–281 (2012).

It’s a simple rule-of-thumb that injection moulding businesses have to extract more and more value and value-per-head from their operations: Low-value and low margin moulding manufacture is not a place to be today. Instead, operating high-value contracts that demand more advanced technology, more investment and more longevity are the balancing act that any contract moulder must master.

Wu, H., Wang, Y., & Fang, M., Study on Injection molding process simulation and process parameter optimization of automobile instrument light guiding support. Adv. Mater. Sci. Eng. https://doi.org/10.1155/2021/9938094 (2021).

Therefore, we chose the grey relation modeling equation to determine the grey relation coefficient. As shown in Eq. (1), the SNR of each single quality feature was normalized by grey correlation generation. The normalized value is between 0 and 1. Subsequently, the deviation sequence (2) was used to calculate the difference between the values of the reference sequence and pretreatment . After data preprocessing, grey correlation analysis (3) was used to process normalized data to calculate grey correlation coefficient, which represents the relationship between actual and ideal normalized analysis results. After calculating the grey correlation coefficient of all 16 iterations, the grey correlation degree (4) was calculated by averaging the grey correlation coefficient values corresponding to each evaluation index.

For many years the British Plastics Federation – Wittmann is a member - has been carrying the torch for the sustainable manufacturing agenda, advised and sustained by its consultant, Dr Robin Kent, an expert practitioner in plastics processing of over 50 years’ standing.

IMAGOxt allows the energy consumption of connected machinery, devices and any consumption clusters in injection moulding to be visualised and displayed in a scalable manner.

Hentati, F. et al. Optimization of the injection molding process for the PC/ABS parts by integrating Taguchi approach and CAE simulation. Int. J. Adv. Manuf. Technol. 104, 4353–4363 (2019).

The current generation of Wittmann’s MacroPower, EcoPower, SmartPower and MicroPower moulding machines have been designed by Wittmann with these factors in mind, and are now the most compact ever made by the company.

Mean and range analyses were performed. The warpage, volume shrinkage, residual stress in the first direction and residual stress in the second direction of the cylinder were selected as the experimental evaluation indexes, and different molding process parameters such as melt temperature, mold temperature, packing pressure, packing time and cooling time were used as the experimental level factors. The results showed that the minimum warpage process combination was A4B2C2D3E3; the minimum volume shrinkage process combination was A1B2C3D3E4; the process combination with minimum residual stress in the first direction was A4B2C1D3E4; the process combination with minimum residual stress in the second direction was A3B2C2D3E2;

Li, K., Yan, S.-L., Pan, W.-F. & Zhao, G. Optimization of fiber-orientation distribution in fiber-reinforced composite injection molding by Taguchi, back propagation neural network, and genetic algorithm–particle swarm optimization. Adv. Mech. Eng. https://doi.org/10.1177/1687814017719221 (2017).

where \(\overline{{I_{{\text{j}}} }}\) —the average value of a certain experimental factor at a certain level ; \(\overline{Y}\)—Mean value of all test factors at all levels.

In this paper, the injection mold for IV-type hydrogen storage cylinder lining is designed. The injection molding process parameters were studied. The optimum combination of process parameters was selected after range analyses of each assessment index. To determine the level of each parameter's effect on the overall assessment index, two additional analytic techniques are used: grey correlation degree and Taguchi and SNR. On this basis, the injection molding process parameters are simulated and verified.

After comprehensively considering the quality requirements of hydrogen storage cylinder lining and actual production experience, five factors were selected, including melting temperature, mold temperature, holding pressure, holding time and cooling time, recorded as A, B, C, D and E, respectively. Based on the number of factors selected in the orthogonal test, four levels of each factor were selected uniformly by combining the recommended parameters and the actual injection molding experience. Table 2 shows the process parameters in the simulation. According to the principle of the orthogonal test, the orthogonal test table L16(45) was established. And the process parameters of 16 combinations in the table were analyzed by Moldflow software.

Kima, H. S., Sonb, J. S. & Imc, Y. T. Gate location design in injection molding of an automobile junction box with integral hinges. J. Mater. Process. Technol. 140, 110–115 (2003).

Anovitz, L., Smith, B. Lifecycle Verification of Tank Liner Polymers; Oak Ridge National Lab. (ORNL): Oak Ridge, TN, USA, (2014). [CrossRef] storage vessel

According to the injection molding results shown in Table 4, the influence order of various process parameters on warpage is: holding time > melt temperature > holding pressure > cooling time > mold temperature.

For many moulders the ‘plug and produce’ aspects of the Wittmann moulding systems give complete peace of mind when it comes to Quality Assurance. Repeatability and reliability become paramount – especially when it comes to contracts such as medical, which typically also need intensive and expensive systems of process validation.

Wittmann is so clear on this issue that WIBA UK offers any prospective customer a free energy audit – an objective and comparative assessment of the energy usage of its machines. A piece of Wittmann software called IMAGOxt represents the tip of the spear for the next phase in this campaign.

Another factor determining the quality of injection parts is process parameters; such as injection temperature, mold temperature and injection time, which they directly affect the production cost and quality. Unreasonable process parameters will lead to different defects in the final product, such as warping, shrinkage and residual stress, thereby reducing the mechanical properties of injection molded parts17,18,19,20. When manufacturing the cylinder liner, the process parameters will affect the quality properties, such as weld marks, under-injection and so on, increasing the waste rate.

Through the analysis of Table 5, a better process parameter group A1B2C3D3E4 can be obtained. When the melt temperature reaches 240 °C, the mold temperature reaches 80 °C, the holding pressure is 60 MPa, the holding time is 20 s, and the cooling time is 8 s. The optimum combination is not in the test times, the optimized molding process parameters are input into Moldflow software for analysis and verification. The final result is shown in Fig. 5. The volume shrinkage rate was 12.66%.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly