Engel Installs World's Largest Tech Center Injection Molding Machine - large inj

Author:gly Date: 2024-09-30

A device called a microcapacitor relies on tantalum to release energy in a quick burst — handy for the phone’s camera flash, for example.

“The world is unrecognizable from 100 years ago,” says Anna Ploszajski, a materials scientist and author of Handmade: A Scientist’s Search for Meaning Through Making. And that, she says, is “simply because of the materials that we have around, let alone all of the new ways we use them.”

In a quest to connect with the omnipresence of plastics, Susan Freinkel, author of Plastic: A Toxic Love Story, pledged to go a day without touching any. Glimpsing her plastic toilet seat, Freinkel gave up the experiment mere moments after it began and instead spent the day cataloging page upon page of plastic stuff she encountered.

Mold maintenance is critical, and with this collection of content we’ve bundled some of the very best advice we’ve published on repairing, maintaining, evaluating and even hanging molds on injection molding machines.

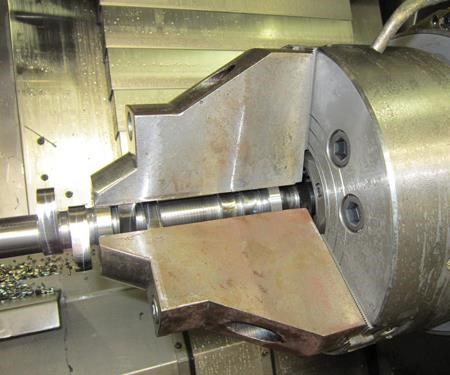

Quick-change tooling on a live-tooling station saves time during production my eliminating the need to touch-off tools each time they are installed.

The examples below highlight just a handful of ways that advances in materials over the last century have transformed our daily lives — we’ve focused on travel, connectivity and convenience. We could have chosen countless others.

In the following decades, catalytic cracking and improvements to the process Houdry pioneered would contribute to the reign of automobiles, and catalytic cracking still produces much of the gas that cars guzzle today.

Improving finish in the grooves between the lobes and increasing lobe machining speed proved to be challenging during testing. However, Tim Whitmore, an OEM project manager for Iscar, work closely with Mr. Kraieski to iron out the tooling issues. By the time the machine was delivered to Comp Cams, it could complete a M4 camshaft core in 75 minutes.

Research advances that led to alloys and composites, as well as plastics — many of which ended up in cars and planes — got a boost from a desire to get to space. Spacefaring vehicles have to be not only strong and lightweight, but also withstand extreme temperatures.

Chemist Stephanie Kwolek (shown) invents Kevlar while looking for light, strong fibers to replace steel wires in car tires.

It was the summer of 1940, the early days of the Battle of Britain. Nazi Germany’s air force, the Luftwaffe, began a months-long attack on the British Isles that eventually included the nightly bombing raids known as the Blitz. Going into the battle, the Luftwaffe believed it had the upper hand; in battles in France, the Germans had dominated in the air. Little did they know the Allies had a secret weapon — and it was in their fuel tanks.

We’ve come a long way from the days of celluloid and Bakelite. Tens of thousands of plastic compounds exist today. We now produce an excess of 380 million metric tons of plastic a year — that’s more than a hundred pounds of what’s typically very lightweight stuff for every person on the planet every year.— Carolyn Wilke

While prices moved up for three of the five commodity resins, there was potential for a flat trajectory for the rest of the third quarter.

Plastics covered her body — in yoga pants, sneakers and eyeglasses. Plastic made up the entire interior of her minivan and parts of kitchen appliances. Plastic packaging protected her food, and after eating, she dumped her trash in a plastic bin. Even the walls around her contained plastics, from the paint to the synthetic insulation.

Each turret has three different grooving tools. Two of those perform roughing operations. The wider of the two is used as often as possible, while the thinner one is used only when space is tight. The third grooving tool is used for finishing, leaving behind a quality, burr-free surface finish while holding dimensional tolerances of less than 0.010-inch on all linear dimensions along a 24-inch-long camshaft.

The photos on the following page show how camshaft cores are produced on the lathe. An operator manually slides a pre-cut bar into the main spindle, pulls the bar out a few inches to a stop, and clamps it. The lathe then turns and mills features into what will become the front face of the cam. Next, the subspindle moves into position, grabs the machined face and pulls out the bar approximately 10 inches. Grooving and lobe milling are completed on that segment of the bar. Once machining on that section is completed, the subspindle clamps onto some of the newly machined journals and pulls the bar farther out of the main spindle to enable grooving and lobe milling of the back half of the camshaft. (Performing these operations in two small sections minimizes the risk of deflection, vibration and chatter.) Finally, the subspindle consumes nearly the entire bar to enable turning and milling work on the back face of the camshaft.

Gifted with extraordinary technical know how and an authoritative yet plain English writing style, in this collection of articles Fattori offers his insights on a variety of molding-related topics that are bound to make your days on the production floor go a little bit better.

Clearly chemists and materials scientists have contributed to these problems. But they will inevitably be part of finding solutions as well. There’s a cyclical nature to the promise and perils of new molecules and materials. “The entire history of chemistry is, ‘Hey, look what I can do! Darn, I wish I hadn’t done it that way! But I have another way I can do it.’ And that keeps us kind of moving forward,” Jones says.

When the Apollo 11 astronauts reentered Earth’s atmosphere after their historic moonwalk in 1969, the outer surface of their module skyrocketed to somewhere around 5,000° Fahrenheit, hot enough to incinerate any living thing. But inside, the astronauts sat at comfortable temperature around 70° F or so, protected by a heat shield made of a material called Avcoat.

Advertisements in Science News in the 1940s through 1960s highlight innovations that promised to change the way people lived and worked. Tap to enlarge

Houdry wasn’t the first to attempt to use catalysts to bust the big molecules of heavy fuels into smaller ones to improve performance. But as an avid road racer, he had a special interest in high-quality gasoline. He studied hundreds of catalysts until he landed on aluminum- and silicon-based materials that could do the busting more efficiently than an existing process that relied on heat. When he tested his gasoline in his Bugatti racer, he reached speeds of 90 miles per hour.

The organic chemistry advances of the early 1900s made new and exciting materials possible, but also allowed people to make more and more materials that weren’t recyclable, says Thomas Le Roux, a historian at the French National Centre for Scientific Research in Paris and coauthor of the 2020 book The Contamination of the Earth. By the 1970s, new disposable products, from pens to razors to packaging, signaled an ease of life. “It was modern to throw away what we buy,” he says.

A leading manufacturer of high-performance valve train components installed a twin spindle/twin-turret lathe to bring camshaft machining work in-house. Here, the company explains how it has become more effective using its multifunction lathe to produce small batches of custom racing camshafts.

Multiple speakers at Molding 2023 will address the ways simulation can impact material substitution decisions, process profitability and simplification of mold design.

As a semiconductor, silicon conducts electricity better than materials such as ceramics and glass do, but not as well as metals. This in-between status makes it possible to control how electrons zip around a semiconductor, a control that’s ideal for creating electrical switches for circuits in radios, televisions or computers. In the 1930s and 1940s these and other electronic devices relied on bulky, breakable glass vacuum tubes that weren’t all that reliable. Decades of semiconductor research pointed to another, slimmer way.

Thousands of people visit our Supplier Guide every day to source equipment and materials. Get in front of them with a free company profile.

Alongside this new science came new and improved scientific tools. Scientists can now see materials at a much finer scale, with the electron microscope making individual atoms visible. X-ray crystallography unveils atomic arrangements, allowing for a better understanding of materials’ structure. And equipment such as chromatographs and mass spectrometers let today’s scientists untangle mixtures of chemicals and identify the compounds within. Francis Aston first took advantage of a mass spectrometer in his study of isotopes in 1919, but for a long time the tool was seen by some chemists as, according to a description by mass spectrometrist Michael Grayson, “an unexplainable, voodoo, black magic kind of a tool.”

technotrans says climate protection, energy efficiency and customization will be key discussion topics at PTXPO as it displays its protemp flow 6 ultrasonic eco and the teco cs 90t 9.1 TCUs.

Plastics, born from chemistry labs and now ubiquitous, provide a quintessential example of the journey from material marvel to environmental nuisance. But they’re not the only problem.

The company ultimately decided to go a different route after Mr. Godbold met with Larry Schwartz, who at that time was Okuma America’s president (he’s now the machine tool builder’s chief strategy officer). The men discussed alternate ways to manufacture camshaft cores that would minimize change-overs and simplify setups for production runs of 20 or so pieces. Mr. Schwartz’s idea was to use a twin-spindle/twin-turret lathe. Keeping a bar either clamped between the spindles and/or partially inside of them would enable complete machining of camshaft cores in one setup. Plus, the twin spindles could perform some operations simultaneously.

Our attention-sucking phones are right in front of our faces. But out of sight are the fiber optics that relay messages around the world in a flash.

The stories of the women who assembled integrated circuits and wove core memory for the Apollo missions remain largely unknown.

Though the two teams independently developed silicon transistors, Texas Instruments’ Gordon Teal gets the credit as his announcement came first, in May of 1954.

The first detailed image of a living brain is taken by a computerized tomography, or CT, scanner in England. Co-inventor of the technology, Godfrey Hounsfield, is shown.

The upper turret has two vertically oriented end mills of different diameters that remain in their respective live stations. These are used in conjunction with the machine’s Y-axis movement to perform lobe milling. The narrower 0.75-inch end mill has one less insert than the 1-inch end mill, so the feed rate has to be reduced when that tool is used. Tools in the upper turret’s five horizontal live stations often don’t change either. These perform drilling, tapping, reaming and other operations on the front face of a camshaft.

After successfully introducing a combined conference for moldmakers and injection molders in 2022, Plastics Technology and MoldMaking Technology are once again joining forces for a tooling/molding two-for-one.

Science News was founded in 1921 as an independent, nonprofit source of accurate information on the latest news of science, medicine and technology. Today, our mission remains the same: to empower people to evaluate the news and the world around them. It is published by the Society for Science, a nonprofit 501(c)(3) membership organization dedicated to public engagement in scientific research and education (EIN 53-0196483).

Space materials push composites to the max. One extreme composite is Nextel. Sheets of it, woven of the ceramic fiber and Kevlar, another materials innovation, protect the International Space Station from debris and meteoroids. In other cases, materials invented for air and space travel have stuck around on Earth. Memory foam, developed in the late 1960s to cushion pilots and passengers during takeoff and landing, is now better known for its use in mattresses. And space blankets, which arrived that same decade to protect electronics from drastic swings of temperature, show up in emergency kits and are donned by marathoners after a race.— Carolyn Wilke

Houdry, after helping to fuel those vehicles, looked again to catalysts to deal with the pollution that internal combustion engines caused. He designed a catalytic converter.

Perhaps the largest unintended consequence that humankind faces today is climate change. Human activities — factories, mining, growing food, traveling, using air conditioning and heating to keep indoor climates comfortable — have released greenhouse gas emissions which have heated the world by around 1.25 degrees Celsius since preindustrial times. The world is already experiencing extreme weather events linked to climate change.

While the major correction in PP prices was finally underway, generally stable pricing was anticipated for the other four commodity resins.

In this collection, which is part one of a series representing some of John’s finest work, we present you with five articles that we think you will refer to time and again as you look to solve problems, cut cycle times and improve the quality of the parts you mold.

Instead of relying on serendipity and trial and error, scientists are learning to assemble atoms and molecules into materials with the mix of properties needed.

This Knowledge Center provides an overview of the considerations needed to understand the purchase, operation, and maintenance of a process cooling system.

Longer 6-inch jaws on the sub-spindle enable it to clamp at least two journals of every camshaft Comp Cams manufactures.

From experiments on natural rubber, Staudinger showed that large, heavy molecules could be formed by the linking of many smaller molecules into chains. As Science News put it in 1953, when Staudinger was awarded the Nobel Prize in chemistry: “The way the molecules regiment themselves determines the differences between springy rubber, hard plastic and tough fiber.” It might sound obvious today, but it was a contentious claim when Staudinger proposed it. Chemists at the time thought that what we now call macromolecules were simply aggregates of smaller molecules.

But dirigibles and duralumin were just the beginning. The 20th century has seen an explosion in types of alloys and their applications, from stainless steel cutlery to the titanium alloys used in prosthetics and pacemakers to crucial components of vehicles. Today’s jet engines are built of superalloys, which can withstand infernal temperatures.

Ultradent's entry of its Umbrella cheek retractor took home the awards for Technical Sophistication and Achievement in Economics and Efficiency at PTXPO.

A new NASA spaceship called Orion, destined to take people to the moon and beyond, again uses Avcoat. But engineers have come up with a far more efficient process to make it. Instead of injecting Avcoat individually into each fiberglass cell, the Avcoat material is now made in pieces, which are machined to size before they are bonded onto a heat shield more than 16 feet in diameter. An Orion test mission to the moon could launch in early 2022.

By the mid-1960s, researchers started noticing plastic pieces in the ocean, says science writer Susan Freinkel, author of Plastic: A Toxic Love Story. Now plastic pollution is found virtually everywhere, in bits wafting in the winds, on Earth’s tallest mountain and as trash piling up on the seafloor.

Prior to the lathe’s delivery, Comp Cams sent what it thought was a very difficult camshaft core to Okuma’s facility for machine prove-out: a 70-mm-diamter NHRA Pro Stock camshaft with nine journals. Kevin Kraieski, an applications engineer for Okuma, created the initial part programs and machined the first sample parts. Mr. Kraieski set up the part program using multiple variable-style sub-routines for commonly required operations, such as grooving between lobes, milling lobe profiles, drilling and tapping bolt hole patterns, and more. This made it possible for Comp Cams to easily reprogram the complex machine for any number of camshaft designs without starting from scratch each time.

Say “manufacturing automation” and thoughts immediately go to the shop floor and specialized production equipment, robotics and material handling systems. But there is another realm of possible automation — the front office.

But all that driving soon began to take a toll on the environment. When the hydrocarbon molecules in gasoline burn, the engine exhaust contains small amounts of harmful gases: poisonous carbon monoxide, nitrogen oxide that can cause smog and acid rain, as well as unburned hydrocarbons. With so many vehicles hitting the road, cities such as Los Angeles choked on smog in the 1940s and ’50s.

Many new materials were birthed from basic curiosity and serendipity. But new techniques also made way for targeted innovation. Today materials can be designed from scratch to solve specific problems. And explorations of the properties of solid substances — for instance, how matter interacts with heat, light, electricity or magnetism — along with iterations of design have further contributed to the stuff that surrounds us, giving way to transistors, transition lenses, touch screens and hard disk drives. Explorations into how matter interacts with biological tissues have yielded coronary stents, artificial skin and also hip replacements, including metal mélanges that are tough and nonreactive when they sit against bone.

For a testament to the power of materials to connect us, just look at an iPhone. “The iPhone contains about 75 elements from the periodic table — a huge proportion of all the atoms that we know about in the universe are in an iPhone,” says Anna Ploszajski, a materials scientist and author of Handmade: A Scientist’s Search for Meaning through Making.

Scooter Brothers certainly understood that when the twin-spindle/twin-turret machine was delivered. As long as long as the company became more effective using the lathe during the first few months and was able to achieve a half-throttle-level of production within a year, Mr. Brothers was not going to be discouraged.

Slosson went on to describe the potential to create aromatics, flavorings, nitroglycerine for dynamite, plastics, drugs and dyes “of infinite variety.” Petroleum would become increasingly valuable “as a source of substances for which man has hitherto been dependent upon the chance bounty of nature.”

Across all process types, sustainability was a big theme at NPE2024. But there was plenty to see in automation and artificial intelligence as well.

At a conference in Dayton, Ohio, toward the end of the day’s talks, Teal matter-of-factly revealed his company’s success. “Contrary to what my colleagues have told you about the bleak prospects for silicon transistors,” he said, “I happen to have a few of them here in my pocket.” His announcement, which followed other talks suggesting that the devices were years away, jolted the audience, which stampeded to the back of the room for copies of Teal’s talk, and out to the telephone booth to share the news.

In the 1950s, Houdry set out his solution, outlining a series of reactions, materials and conditions necessary for a working catalytic converter. But he was ahead of his time. For years, the adoption of catalytic converters in automobiles was stymied by leaded gasoline, which improved octane ratings but gummed up the catalysts’ surfaces. Within a few decades of the passage of the Clean Air Act of 1970, which led to requirements for catalytic converters and lead-free fuel, the devices helped clear the air in cities around the world.

Of all the science headlines of the 1920s, “Ice Cream from Crude Oil” may best capture the era’s unbridled enthusiasm for chemistry. Edwin E. Slosson, the first head of the news service that would become Science News, reported that fats can be made by breaking up and rearranging the molecules of mineral oil. Synthetic ice cream was just one of the wonders that could lie around the corner.

Catalysts boost chemical reactions by reducing the energy needed to get them going. French mechanical engineer Eugene Houdry had developed a catalytic process in the late 1930s to make high-octane fuel, which can withstand higher compression and allows engines to deliver more power. Simply increasing the octane rating of aviation fuel from 87 to 100 gave the Allies a crucial edge.

Glass or ceramic casings frequently feature a band of metal (titanium, aluminum or stainless steel, which is an alloy of iron, carbon and chromium) to protect their edges.

The lathe then turns and mills features into the front face of the camshaft. Next, the sub-spindle pulls the bar out for grooving...

Composites also show up all over today’s cars, from dashboards to bumpers, with various materials glued together to better protect driver and passengers. “The incredible use of adhesives in cars to create crumple zones so that the passenger compartment is safer,” for example, is “directly out of materials,” says Mark Jones, a chemist and member of the National Historic Chemical Landmarks committee of the American Chemical Society.

Studies of the properties of polymers and how to make them continued over the following decades. In the early 1950s, researchers at Phillips Petroleum Company figured out how to use chromium oxide catalysts to transform products left over from the refining of petroleum into polypropylene and polyethylene. Heat- and shatter-resistant, the high-density polyethylene produced by this process is used in products such as hula hoops and baby bottles. It’s one of the most commonly used plastics.

Machining simulation is performed after a program is created for a new camshaft design. After that, a dry run is performed on the lathe followed by a test part created from low-cost mild steel. Once the process is verified, production can ensue in the specified material.

Alloys have existed since ancient times. Bronze Age artisans combined copper with arsenic or tin in crucibles to make tools, jewelry and more. From there, advances coincided with the ability to melt metals at higher and higher temperatures, eventually leading to steel. Scientists since have studied how materials’ structures and properties — including desirable features like strength, bendability and resistance to corrosion — vary with composition, temperature and processing.

This Adcole cylindrical coordinate measuring machine orients camshafts vertically for measurement results that require no need for sag correction. It takes less than a minute for an operator to enter camshaft feature specifications to measure.

PFAS are linked to obesity, cancers and more. Growing evidence of the chemicals’ risks has prompted new guidance for safe drinking water and consumer testing.

When I first spoke to Billy Godbold, he was at a track watching a professional drag racing team test a custom camshaft. Mr. Godbold is the engineering group leader for Comp Cams, the valve train component manufacturer that supplied the camshaft. One month earlier, Comp Cams’ design group had just started contemplating camshaft materials and geometries for this application. Moving from design to completed billet camshaft so quickly would not have been possible years ago when the company outsourced the machining of its high-end racing camshafts.

The polymer Teflon, invented by accident in 1938 at DuPont and famous for its use in nonstick kitchenware, now also shows up in the minuscule microphones in our phones and computers. A Bell Labs effort discovered that when Teflon is coated with aluminum, it holds enough of a charge to pick up sound without being electrified.

An accident at the Chernobyl nuclear power plant in Ukraine killed or sickened dozens of workers and released radioactive material into the environment, requiring the evacuation and resettlement of hundreds of thousands of residents.

In a time where sustainability is no longer just a buzzword, the food and beverage packaging industry is required to be at the forefront of this innovation. By adopting circular packaging processes and solutions, producers can meet regulatory requirements while also satisfying consumer demand and enhancing brand reputation. Join Husky to learn more about the broader implications of the circular economy — as well as how leading brands are leveraging this opportunity to reduce costs, increase design flexibility and boost product differentiation. Agenda: The cost and operational benefits of embracing circularity Key materials in circular packaging — including rPET and emerging bioplastics How to design a circular food and beverage package Strategies for selecting sustainable closures to future-proof packaging solutions Optimization and streamlining of production processes for enhanced efficiency How Husky Technologies can enable your sustainable success

Take a deep dive into all of the various aspects of part quoting to ensure you’ve got all the bases—as in costs—covered before preparing your customer’s quote for services.

Astronauts in the Apollo 11 command module (left) were protected from high temperatures during reentry through Earth’s atmosphere (right) by a heat shield made of a material called Avcoat.

As it turned out, the “really difficult” camshaft Comp Cams sent to Okuma for testing proved easier to machine than its other camshaft models. That’s because the camshaft’s nine journals provided more clamping points for the subspindle than a typical five-journal camshaft. Consequently, the original subspindle jaws were not long enough to clamp across at least two journals on the five-journal models (this was necessary to ensure adequate support during machining). Installing lengthier 6-inch jaws enabled the subspindle to clamp across two or more journals on any type of camshaft the company manufactures. The main spindle always clamps solid barstock, so longer jaws are not necessary for that spindle.

Join Wittmann for an engaging webinar on the transformative impact of manufacturing execution systems (MES) in the plastic injection molding industry. Discover how MES enhances production efficiency, quality control and real-time monitoring while also reducing downtime. It will explore the integration of MES with existing systems, emphasizing compliance and traceability for automotive and medical sectors. Learn about the latest advancements in IoT and AI technologies and how they drive innovation and continuous improvement in MES. Agenda: Overview of MES benefits What is MES? Definition, role and brief history Historical perspective and evolution Longevity and analytics Connectivity: importance, standards and integration Advantages of MES: efficiency, real-time data, traceability and cost savings Emerging technologies: IoT and AI in MES

Plastics Technology’s Tech Days is back! Every Tuesday in October, a series of five online presentations will be given by industry supplier around the following topics: Injection Molding — New Technologies, Efficiencies Film Extrusion — New Technologies, Efficiencies Upstream/Downstream Operations Injection Molding — Sustainability Extrusion — Compounding Coming out of NPE2024, PT identified a variety of topics, technologies and trends that are driving and shaping the evolution of plastic products manufacturing — from recycling/recyclability and energy optimization to AI-based process control and automation implementation. PT Tech Days is designed to provide a robust, curated, accessible platform through which plastics professionals can explore these trends, have direct access to subject-matter experts and develop strategies for applying solutions in their operations.

The story of commercial plastics began in the 1860s, when John Wesley Hyatt, seeking a substitute for the ivory popularly used in billiard balls, landed on a material later called celluloid. It made its way into combs, other novelties and photographic film. But cellulose, a natural substance, was at its heart; it wasn’t fully synthetic.

This month’s resin pricing report includes PT’s quarterly check-in on select engineering resins, including nylon 6 and 66.

Staudinger’s ideas gradually gained acceptance and formed a basis for new research on polymers. In the following decade, industrial chemists worked to figure out the chemical reactions needed to create new polymers, plastics among them. One early success story was nylon, invented in 1935 as a substitute for silk. American women were introduced to nylon stockings in 1940 and they proved a hit — in a year, nylons accounted for 30 percent of the hosiery market.

Shortly after catalytic cracking was first demonstrated at industrial scale in 1937, Science News Letter, the predecessor of Science News, described it as “a radically new refining process held to be of the greatest importance to the entire petroleum industry.” By then Houdry had moved to the United States and joined Socony-Vacuum Oil and Sun Oil to build pilot plants. The first large-scale “Houdry unit” began operating at Sun Oil’s Marcus Hook refinery in Pennsylvania, and units multiplied from there.

Each turret on the LT-300MY has 12 tool stations. Daniel Freeman, the R&D technician for Comp Cams who commonly programs and helps run the lathe, says the company takes full advantage of those 24 total stations. Approximately two-thirds of them rarely change. In addition, tools in several stations are mirrored on both the upper and lower turrets to facilitate the simultaneous machining operations.

Successfully starting or restarting an injection molding machine is less about ticking boxes on a rote checklist and more about individually assessing each processing scenario and its unique variables.

DDT first arrives in the United States (1945 treatment shown), with immediate implications for curbing the spread of insect-borne diseases. In 1972, amid concerns of its toxicity to humans and other animals, William Ruckelshaus, Environmental Protection Agency administrator, announces the cancellation of all uses of DDT in the United States.

Resin supplier Celanese turned to startup Rafinex and its Möbius software to optimize the design for an engine bracket, ultimately reducing weight by 25% while maintaining mechanical performance and function.

Learn about sustainable scrap reprocessing—this resource offers a deep dive into everything from granulator types and options, to service tips, videos and technical articles.

Researchers are exploring how to “merge the rigid, brittle materials of conventional electronics with the soft, curving surfaces of human tissues.”

Despite the challenges and environmental hazards associated with mining them, these elements show up in a lot of other 20th century applications, too. Rare earths are in color televisions, camera lenses, fiber-optic cables, nuclear reactors, nickel-metal hydride batteries, aircraft engines, PET scanners and much more.

Your smartphone is a marvel of materials science. Chemical elements from across the periodic table join forces to power your double-tapping and scrolling obsession. Here’s a sampling of those elements, both familiar and exotic. — Carmen Drahl

Plastics and composites have also helped planes shed weight. While alloys melt metals and sometimes other types of elements together, composites combine materials with very different properties — such as glass and plastic — by suspending one in the other or sandwiching them together, for instance. Because they can be tuned to be light and strong, composites have made their way into parts all over planes, from the engine to the wings. Boeing’s 787 Dreamliner, which debuted in 2007, is made up of 50 percent composites by weight.

Another early challenge was getting used to P codes, which are used to synchronize the motion of the two turrets. P codes not only ensure that the turrets don’t interfere with each other when performing separate operations, but also can signal them to perform identical operations simultaneously. For example, if a programmer wants to face a part with the upper turret and then drill the end of it with the lower turret, those operations have to be synchronized because they obviously can’t be performed at the same time. If the programmer assigns a P10 value to the upper turret and a higher P20 to the lower turret, the upper turret will continue all of its necessary motions until it encounters a higher P value in the program code. If the next P code it encounters is higher than the P code assigned to the lower turret, the upper turret will wait until lower turret is done. However, if the same P code is applied to both turrets, they will work simultaneously.

Comp Cams’s goal is to be a leading developer of innovative valve train components, Mr. Godbold explains. Machining is viewed as a means to that end. Mr. Godbold says companies with a similar approach are well-served to recognize their manufacturing limitations, especially when considering the addition of a complex lathe like the LT-300MY. It’s best to devote some time to learning the ins and outs of such a machine before depending on it for production, he notes.

The outputs of such efforts are all around us. Take air travel, for example, and the global interconnectivity it introduced. It’s possible thanks to alloys that are lightweight and robust. And today’s personal connectivity — via smartphones and computers — came with transistors made of silicon. Their small size and low power requirements brought computing to work, and then into our homes and pockets. An abundance of plastic housewares and comfy athleisure options are made possible via improvements in polymers.

As Germans began flying over England, they were surprised to find the tables had turned. One important factor was not the planes themselves, but the octane rating of the fuel they ran on. The British Spitfires and Hurricanes that the Germans had outmaneuvered in France could now climb higher and fly faster thanks to fuel made with a newly developed process called catalytic cracking.

Chemistry and materials innovation can’t solve all our problems. People’s choices will also matter. Weighing the risks and rewards associated with new materials will require recognition of the potential problems, regulations to combat them, willpower, collaboration and collective action. History holds plenty of lessons, but it’s not yet clear whether we’ll learn from them.— Carolyn Wilke

AT&T’s new television process is described; it uses photoelectric cells. Herbert Hoover is shown here in a public demonstration.

A coating that contains indium, tin and oxygen conducts electricity and senses the salt and moisture on your fingertips.

With it acquisition of DuPont’s engineering resins, Celanese’s resin solutions for automotive electrification, e-mobility and consumer electronics are plentiful.

The history of science offers up abundant examples of solutions begetting new problems. Polychlorinated biphenyls, or PCBs, which proved useful as insulators in electronics, can cause serious health problems when they enter the environment, including cancer. The compounds that allow food to slide without sticking out of kitchen pans belong to a family that have earned the title “forever chemicals” for their tendency not to degrade. Lithium mining, which has increased with demand for lithium-ion batteries, guzzles water and can release harmful chemicals that contaminate ecosystems and poison drinking wells. Other battery ingredients, such as cobalt, are mined unethically — sometimes using child labor.

Typically made of glass, though sometimes of plastic, these strands carry information in light coursing through their cores. A second layer prevents the light’s escape by bouncing it inward. The glass has to be ultrapure, free from foreign atoms, and so is grown from the bottom up. Gas molecules are deposited onto a rod that is later removed, a strategy figured out in the 1970s.

After adjusting the amount of magnesium in his mixture one day in 1906, Wilm left for the weekend, charging his assistant to test the hardness again on Monday. To their surprise, they discovered a new, never-before-seen feature of some alloys: Simply sitting at room temperature, the material had gotten harder as it sat.

And powering our phones are lithium-ion batteries that became commercially available in 1991, after nearly two decades of iterations that are ongoing still. Researchers sought materials that more readily give up electrons for the batteries’ anodes and materials that better attract them from the cathodes, while also swapping materials to keep the batteries lightweight and reduce the likelihood of explosions.

Air travel for the masses encountered a different dilemma: lightening the load. The earliest airplanes gained lift at the turn of the 20th century on wings of fabric and wood, but to really soar, airplanes needed light but strong materials. The first aircraft designed for passengers, the Ford Trimotor — nicknamed the Tin Goose — took to the air in 1926 with help from aluminum alloys.

Yet it wasn’t until the 1920s that researchers started to understand plastics’ chemical nature. Plastics are a type of polymer, large molecules made of repeating units. At the time, what gave natural polymers like cellulose, shellac and rubber their properties remained unknown. Inventors seeking new human-made substitutes for these materials could land on something similar, but it was a trial-and-error endeavor. Credit for changing all that goes to the German organic chemist Hermann Staudinger.

Yet innovation hasn’t come without consequences. For each tale of progress, there are also stories of the marks people have left on this planet. While enabling humans to flourish, many new substances have become pollutants, from PCBs to plastics. However people go about addressing these environmental problems, other new materials will inevitably play a role in the solutions.— Carolyn Wilke

An implanted grid of electrodes called BrainGate allows a paralyzed man to check his e-mail and play games with his brain activity alone.

Luckily for me, “you can’t sell if you don’t tell” is the motto of Paul “Scooter” Brothers, one of Comp Cams’ owners as well as chairman of the board for the Specialty Equipment Market Association. In keeping with the spirit of that saying, company representatives weren’t shy about detailing how they’ve become better at using the advanced lathe during my visit to their Memphis, Tennessee facility.

Comp Cams has refined this process to the point that it can now machine camshaft cores in 35 to 45 minutes. That said, the company had to overcome some initial machining hurdles in order to achieve these faster cycle times.

Processors with sustainability goals or mandates have a number of ways to reach their goals. Biopolymers are among them.

But Freon and its CFC cousins had unforeseen consequences on the atmosphere when they escaped air conditioning and refrigeration systems. In the 1980s, scientists discovered a hole in Earth’s ozone layer, created when CFCs rise to the stratosphere, break down and react with ozone, destroying it. In solving one problem, humanity found itself with another.

The lower turret contains center drills used for both the front and rear camshaft faces. This turret also has live horizontal stations set up to create features such as vent holes. Two stations contain miscellaneous tools. These include a multifunction drilling/boring tool that is typically used to create counterbores, and a large indexable-insert drill that machines bores on the rear of a camshaft.

After retractions from Ranga Dias’ group, high-pressure physicists are feeling the squeeze, fearing the controversy will tarnish other research.

Across the show, sustainability ruled in new materials technology, from polyolefins and engineering resins to biobased materials.

Chemists are fashioning fibers and fabrics from cow’s milk, trees, coal, fish and sand – with stranger sources still to come.

In this collection of articles, two of the industry’s foremost authorities on screw design — Jim Frankand and Mark Spalding — offer their sage advice on screw design...what works, what doesn’t, and what to look for when things start going wrong.

The company selected an Okuma LT300-MY. Mr. Godbold says that in many ways, the initial concept and programming execution were greater hurdles than the slight machine modifications that were needed for this application. The primary mechanical change to the machine was increasing the size of the sleeves in the main and subspindles so a 70-mm-journal camshaft could pass through them. The company reasoned that because the machine offered a great deal of rigidity and each of its spindles provided 30 horsepower, the lathe would have no problem machining the tough M4 powder-metal tool steels (rated at 30 HRc) common to its billet racing camshafts.

The Plastics Industry Association (PLASTICS) has released final figures for NPE2024: The Plastics Show (May 6-10; Orlando) that officially make it the largest ever NPE in several key metrics.

The aim of this presentation is to guide you through the factors and the numbers that will help you determine if a robot is a smart investment for your application. Agenda: Why are you considering automation? What problems are you trying to solve? How and why automation can help Crunch the numbers and determine the ROI

Sony releases the first commercial lithium-ion battery (a more modern battery is shown), clearing the way for abundant portable electronics.

All of these developments and more led to today’s abundance of electronic devices. But ever more improvements, and our constant urge to upgrade, creates a new problem: “How do we unmake this stuff and recycle those substances safely?” asks Ploszajski.— Carolyn Wilke

Join Engel in exploring the future of battery molding technology. Discover advancements in thermoplastic composites for battery housings, innovative automation solutions and the latest in large-tonnage equipment designed for e-mobility — all with a focus on cost-efficient solutions. Agenda: Learn about cutting-edge thermoplastic composites for durable, sustainable and cost-efficient battery housings Explore advanced automation concepts for efficient and scalable production See the latest large-tonnage equipment and technology innovations for e-mobility solutions

The company uses Exsys/Eppinger Preci-Flex ER32 quick-change adaptors for some of its live-tooling work. Each adaptor can accommodate a drill, tap or mill for use in that single station. During setup, each tool is separately installed in the adaptor and touched off. During a production run, a program stop pauses the machine and prompts the operator to change the tool in the adaptor station to the next tool needed. The operator can change the tool in less than one minute, and touch-off isn’t necessary because the offset for each tool was determined during setup. Mr. Freeman says tools in the adaptor extend out a couple inches farther than normal, but this does not present any clearance issues.

Plastics Technology covers technical and business Information for Plastics Processors in Injection Molding, Extrusion, Blow Molding, Plastic Additives, Compounding, Plastic Materials, and Resin Pricing. About Us

The camshaft portion of Comp Cams’ product line is evenly divided into three segments: high-performance/non-racing applications; hobbyist racers; and engine builders for NASCAR, NHRA and other professional race teams. The custom billet camshafts machined in the company’s Memphis facility are used by the professional race teams.

But it was World War II that drastically increased demand for plastics. The military turned to the new industry to make substitutes for strategic materials such as glass, brass or steel, says Freinkel. World War II called for nylon’s diversion to military uses, so women offered up their stockings to be recycled. “Great piles of stockings retired after faithful and intimate service are awaiting resurrection — thousands of pounds of them,” reported a 1943 Science News article.

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Edwin E. Slosson, director of Science Service, reports on “some of the achievements and hopes of modern chemistry” from a meeting in Philadelphia. “Ice cream made from crude oil is one of the many marvels….”

Mr. Godbold explains that Comp Cams’ traditional expertise was in grinding camshafts, not machining them. So when the decision was made to install the seven-axis multifunction lathe in 2008, the company relied heavily on the expertise and advice of its equipment suppliers to establish an effective machining process. Comp Cams continues to tap those resources today as it strives to minimize cycle times for camshaft cores.

All the glass strung out in the world’s optical cables could tether Earth to Uranus and then some, stretching some 4 billion kilometers. These cables ferry messages across countries and continents and across the seafloor. Optical fiber “really has strung the world together in a new way,” says Ainissa Ramirez, a materials scientist and author of the book The Alchemy of Us. Messages from across the Atlantic used to come by boat, she says, then came copper cables to relay telegraph dispatches in the 1840s. The first live telephone traffic sent through fiber-optic cables was in 1977 in Long Beach, Calif. Now e-mails from abroad arrive nearly instantaneously thanks to thin-as-hair optical fibers. People “have a new relationship with the dispatches that we get as a result of technology,” Ramirez says. “Of course, the internet is changing everything.”

Study shows the plastic compounding process is being used to boost electrical properties and UV resistance while custom compounding is increasingly being used to achieve high-performance in plastic-based goods.

Introduced by Zeiger and Spark Industries at the PTXPO, the nozzle is designed for maximum heat transfer and uniformity with a continuous taper for self cleaning.

Join KraussMaffei for an insightful webinar designed for industry professionals, engineers and anyone interested in the manufacturing processes of PVC pipes. This session will provide a comprehensive understanding of the technology behind the production of high-quality PVC pipes: from raw material preparation to final product testing. Agenda: Introduction to PVC extrusion: overview of the basic principles of PVC pipe extrusion — including the process of melting and shaping PVC resin into pipe forms Equipment and machinery: detailed explanation of the key equipment involved — such as extruders, dies and cooling systems — and their roles in the extrusion process Process parameters: insight into the critical process parameters like temperature, pressure and cooling rates that influence the quality and consistency of the final PVC pipes Energy efficiency: examination of ways to save material and energy use when extruding PVC pipe products

The promise of plastic was on display in 1946. Held in New York City, the first National Plastics Exhibition featured wares made of the wonder material, and some 87,000 people visited. “Thousands of people lined up to go to this trade show and walk through this conference hall and gawk at stuff that had an almost magical quality,” says Freinkel. Visitors saw durable nylon fishing line and window screens in a riot of colors. Such items seemed transformative — mass-produced plastic offered “a new way to have the good life on the cheap.”

The turn of the 20th century set the stage for a new era of materials. Organic chemists learned how to turn coal into a variety of industrial chemicals, including dyes and perfumes. Later, motivated by wartime demand, chemists honed their craft with poison gas, explosives and propellants, as well as disinfectants and antiseptics —so many new products that World War I was often called “the chemist’s war.” And at a fundamental level, the new century also ushered in greater understanding of chemical bonds and the atom, its constituents and its behavior.

The brains of your phone, the chip, is pure silicon with small amounts of other elements added to give it superior electronic properties.

In the decades that followed, approaches in chemistry and physics combined with engineering to give rise to a new field, now called materials science. A boost from the U.S. government, which was seeking new materials for space and military technologies during the Cold War, led to academic departments that brought together physicists, chemists, metallurgists and electrical engineers — anyone interested in materials.

Workpiece slippage inside the jaws also proved to be problematic at times because some camshaft materials are more difficult to clamp tightly than others. The solution was applying a tungsten-alloy coating from Carbonite Metal Coatings on the gripping surface of the jaws. This particular coating is applied via electrofusion, which creates a metallurgical bond that is said to be stronger than spray-on coatings. The coating has virtually eliminated linear and angular workpiece slippage from occurring during machining.

Formnext Chicago is an industrial additive manufacturing expo taking place April 8-10, 2025 at McCormick Place in Chicago, Illinois. Formnext Chicago is the second in a series of Formnext events in the U.S. being produced by Mesago Messe Frankfurt, AMT – The Association For Manufacturing Technology, and Gardner Business Media (our publisher).

Today, Comp Cams machines small batches of racing camshaft cores on a twin-spindle/twin-turret lathe from Okuma. (Camshaft cores are camshafts that have their primary features machined, but still require subsequent heat treating and grinding operations.) Bringing this machining capability in-house enabled the company to greatly speed turnaround of custom camshafts for professional racing applications because it no longer had to wait weeks or months to receive camshaft cores. It can now manufacture as many as 12 M4 powder-metal tool-steel camshaft cores in a single eight-hour shift.

Unless a camshaft has an odd number of grooves, the lathe performs turning and grooving operations using both turrets simultaneously when the bar is held between spindles. Because the upper turret is optimized to run close to the main spindle and the lower one is set up to run close to the subspindle, the company does not perform pinch turning. However, Mr. Godbold estimates that simultaneous cutting enables the lathe to remove material 30 percent faster primarily because the tool pressure is balanced. In addition, starting the grooving operations at the middle of each section of bar and moving out toward the spindles leaves more stock at either end of the bar section. This ensures rigid support to prevent chatter and also eliminates flexing at weak areas of the bar, which could possibly pinch or break a grooving tool.

John Bardeen, William Shockley and Walter Brattain (shown from left to right) of Bell Laboratories demonstrate the transistor, which would replace vacuum tubes and pave the way for modern computing.

Today, we’re awash in plastics. Yet at the beginning of the 20th century, only a handful of plastics had made their way into homes.

Once that section is completed, the sub-spindle consumes the machined section and pulls the bar out further to repeats those operations on the back section of bar.

Metal casings used to be popular, but glass and ceramics (the latter sometimes with zirconium) are better for wireless charging.

Despite price increase nominations going into second quarter, it appeared there was potential for generally flat pricing with the exception of a major downward correction for PP.

Plastic is a common choice for a lightweight and sturdy back of the phone, and frequently includes flame retardant compounds containing phosphorus and occasionally chlorine.

As wartime demand dried up, the plastics industry began to bring more plastics to the people. “That’s really where you start to get this flood of plastic into everyday life,” Freinkel says.

The first fully synthetic plastic, Bakelite, arrived in 1907, discovered unexpectedly as Belgian-born chemist Leo Baekeland sought an alternative to the natural shellac that insulated electrical cables. Celluloid was a suitable substitute for ivory and tortoiseshell, but sleek, shiny Bakelite gleamed with modernity. It quickly made its way into a host of products, including the casings for radios, jewelry and telephones. A new era of innovating on nature’s materials, rather than merely mimicking them, was born, Freinkel writes.

The transistor serves as an example of the coming age of “molecular engineering” – “designing a new material to fit a special purpose.”

There are parallels with how catalytic cracking played out. Mechanical engineer Eugene Houdry invented the process, which ultimately helped enable abundant automobile travel. But, concerned with the health risks automobile pollution created, he invented a catalytic converter to clean up emissions.

The fuselage of the Tin Goose contained a newly developed alloy named duralumin, a contraction of “Dürener” (for the company that originally made it) and “aluminum.” Developed by Alfred Wilm, a German metallurgist seeking a lighter alloy that could replace brass in ammunition cartridges, duralumin combined aluminum with copper, magnesium and manganese and got its strength from a series of heat treatments.

“When first considered, the problem seems simple,” Houdry wrote in a 1954 patent application. “A great number of catalysts can be used for the reaction. By simply placing one of these catalysts in the exhaust line under controlled conditions, the exhaust fumes can be cleaned.” The catalysts, precious metals such as platinum or palladium, provide docking sites for the harmful gases to hang onto; there, reactions involving oxygen convert them to less harmful forms. But, as Houdry pointed out, the high temperatures, mechanical shock and other conditions in an engine complicate the problem.

Exhibitors and presenters at the plastics show emphasized 3D printing as a complement and aid to more traditional production processes.

An extensive survey of the field, put together by the National Academy of Sciences in the 1970s and titled Materials and Man’s Needs, defined materials as “substances having properties which make them useful in machines, structures, devices and products.” Here’s how the report described the pace of research: “The transitions from, say, stone to bronze and from bronze to iron were revolutionary in impact, but they were relatively slow in terms of the time scale. The changes in materials innovation and application within the last half century occur in a time span which is revolutionary rather than evolutionary.”

Chemists are now creating plastics that break down on purpose and can be recycled more easily. Materials scientists are developing better membrane materials to filter pollutants out of water. Engineers are deploying new materials to capture carbon dioxide at smokestacks. New iron-based catalysts could someday convert carbon dioxide into jet fuel, potentially cutting greenhouse gas emissions from air travel. And researchers continue to innovate to turn more and more of the solar spectrum into energy, and so cut our reliance on fossil fuels.

In this collection of content, we provide expert advice on welding from some of the leading authorities in the field, with tips on such matters as controls, as well as insights on how to solve common problems in welding.

Sustainability continues to dominate new additives technology, but upping performance is also evident. Most of the new additives have been targeted to commodity resins and particularly polyolefins.

Sometimes, new materials started out as chemical curiosities, with researchers then figuring out how the materials could be useful. The liquid crystal displays in today’s smartphones and televisions, for example, were born from research in the 1960s exploring how electricity jostles molecules in a liquid. That shake-up changes the molecules’ interaction with light, an innovation first put to use in a calculator’s display.

Resin drying is a crucial, but often-misunderstood area. This collection includes details on why and what you need to dry, how to specify a dryer, and best practices.

Petroleum-based ice creams never became the new it thing, yet Slosson’s reporting was on point. The last century has witnessed a dramatic leap in the ability to study and synthesize matter. From our homes and cities to our electronics and clothing, much of what we interact with every day is made possible through the manipulation, recombination and reimagination of the basic substances nature has provided.

Some of those are rare-earth elements, a set of 17 metallic elements mostly on the outskirts of the periodic table. Though they are difficult to mine and process, rare earths are sought after because they lend unusual magnetic, fluorescent and electrical properties to materials made from them. Neodymium, for example, mixed with other metals makes the strongest magnets known — these magnets make your cell phone vibrate and its speakers produce sound.

While the melting process does not provide perfect mixing, this study shows that mixing is indeed initiated during melting.

“Materials science and engineering over the millennia have gone from ‘What do you find outside the cave?’ to the beginnings of materials-by-design,” Stephen H. Carr of Northwestern University told Science News in the 1980s.

When, how, what and why to automate — leading robotics suppliers and forward-thinking moldmakers will share their insights on automating manufacturing at collocated event.

Though small at the start of the war, the plastics industry got better at making its wares and boosted production. Processes such as injection molding, which spurts melted plastic into a mold “sort of like a Play-Doh Fun Factory,” Freinkel says, made it possible to mass-produce plastic. A technique called blow-molding, invented in the 1930s and based on the same principle as glass blowing, also helped, making a quick way to form plastic bottles.

While prices moved up for three of the five commodity resins, there was potential for a flat trajectory for the rest of the third quarter.

One advantage of standardization is that it minimizes the number of tools that must be touched-off for a new job. Typically, an operator has to install and touch-off only a few drills, reamers and taps during setup for a new job. Tool standardization also enables programmers to quickly and easily determine whether additional tooling is needed for a new project. Ultimately, standardization has enabled Comp Cams to reduce change-over times for most new jobs from an entire day to just a few hours.

E.I. du Pont de Nemours & Co. prepares to market nylon (waterproofing test shown). The synthetic “silk” fiber was invented by chemist Wallace Hume Carothers.

Join this webinar to explore the transformative benefits of retrofitting your existing injection molding machines (IMMs). Engel will guide you through upgrading your equipment to enhance monitoring, control and adaptability — all while integrating digital technologies. You'll learn about the latest trends in IMM retrofitting (including Euromap interfaces and plasticizing retrofits) and discover how to future-proof your machines for a competitive edge. With insights from industry experts, it'll walk you through the decision-making process, ensuring you make informed choices that drive your business forward. Agenda: Maximize the value of your current IMMs through strategic retrofitting Learn how to integrate digital technologies to enhance monitoring and control Explore the benefits of Euromap interfaces and plasticizing retrofits Understand how retrofitting can help meet new product demands and improve adaptability Discover how Engel can support your retrofitting needs, from free consultations to execution

The electron microscope is invented by Max Knoll and Ernst Ruska (shown), allowing for the investigation of a wide range of materials, including biological samples.

Many of our modern substances, plastics and beyond, were created to solve problems, says Mark Jones, a chemist and member of the National Historic Chemical Landmarks committee of the American Chemical Society. For instance, before the 1930s, air conditioning and refrigeration relied on ammonia, which is flammable and toxic. That changed with the introduction of Freon and other chlorofluorocarbons, or CFCs for short, which were created by chemists in the 1920s. These molecules appeared to have little effect on living things. “They were presumed to be incredibly safe,” says Jones, who recently retired from a role in communications at Dow Chemical.

Mike Sepe has authored more than 25 ANTEC papers and more than 250 articles illustrating the importance of this interdisciplanary approach. In this collection, we present some of his best work during the years he has been contributing for Plastics Technology Magazine.

Additive technology creates air pockets in film during orientation, cutting down on the amount of resin needed while boosting opacity, mechanical properties and recyclability.

Metal alloys that frequently include tin and lead glue the electronics together, though companies are working to phase out lead.

Most phones have a lithium-ion battery in an aluminum housing. The battery’s positive electrode, or cathode, is typically lithium cobalt oxide and the negative electrode, or anode, is graphite (a crystalline form of carbon). Some cobalt mining exploits workers, so manufacturers are trying to replace cobalt with other elements such as manganese.

The consequences of this easy-come, easy-go relationship with our stuff soon appeared in the environment. Our unabated demand for fossil fuels, used not only as fuel but as raw materials for making plastics, releases emissions that contribute to Earth’s changing climate.

In this three-part collection, veteran molder and moldmaker Jim Fattori brings to bear his 40+ years of on-the-job experience and provides molders his “from the trenches” perspective on on the why, where and how of venting injection molds. Take the trial-and-error out of the molding venting process.

August 29-30 in Minneapolis all things injection molding and moldmaking will be happening at the Hyatt Regency — check out who’s speaking on what topics today.

The first semiconductor switch, dubbed the transistor, was made of germanium and invented at Bell Laboratories in 1947. But teams at Texas Instruments and Bell Labs were both eyeing silicon instead. Silicon holds up under higher temperatures (the temperatures that might show up in military applications — in a rocket, for example). Silicon is also less likely than germanium to leak current when a switch is supposed to be off. But achieving silicon success depended on the creation of high-purity forms and, as with germanium transistors, the ability to tune its electrical properties by incorporating other atoms.

Mixed in among thought leaders from leading suppliers to injection molders and mold makers at the 2023 Molding and MoldMaking conferences will be molders and toolmakers themselves.

Avcoat is a type of reinforced plastic, made from an epoxy resin filling a honeycomb fiberglass network. A layer of it, which varied in thickness from 0.5 to 3 inches, dissipated heat away from the command module’s metal components, keeping temperatures inside from rising.

In a 1975 Science News article, reporter John Douglas hailed this technology that could carry many more messages than existing clogged communications systems. “Where wires once sufficed … a glut of messages has begun to tax the intrinsic limits of present technology.” Other elements are added into the glass that help amplify the signals. The composition is tuned to a tee to provide the necessary optical properties. The light moving through optical fibers often comes from lasers, another materials-driven technology.

Core Technology Molding turned to Mold-Masters E-Multi auxiliary injection unit to help it win a job and dramatically change its process.

Discover how artifical intelligence is revolutionizing plastics processing. Hear from industry experts on the future impact of AI on your operations and envision a fully interconnected plant.

With that said, the company continues to work closely with Rex Luxmore, its Iscar tooling representative, who Mr. Freeman says is proactive about keeping him up to date with new tooling developments. For example, Mr. Luxmore’s recommendation of grooving tools with a new coating resulted in a 30- to 50-percent improvement in tool life. This assistance is critical, Mr. Freeman notes, largely because of the challenging materials such as M4 powder-metal tool steel that the company frequently machines. This tool steel is not only very unforgiving, but it will work-harden quickly if cut too slowly or lightly.

Mr. Godbold believes this approach made all the difference in the world. He humbly says that Comp Cams proves that a shop with only conventional turning and milling experience can successfully integrate a complex multifunction machine without necessarily being outstanding at machining or programming. However, this requires establishing solid relationships with equipment suppliers that are willing to help a shop achieve its goals. Finding trusted people to work with means everything, he says.

Second quarter started with price hikes in PE and the four volume engineering resins, but relatively stable pricing was largely expected by the quarter’s end.

In a discovery that portends the possibility of atomic bombs, Otto Hahn (right) and Fritz Strassmann report evidence that uranium atoms produce barium when bombarded with neutrons. As explained by their collaborator Lise Meitner (left) and her nephew Otto Frisch, this is fission, the splitting of atoms.

Eliminating the need to contact each supplier for every individual quote, a new CRM for automotive supplier Axiom Group tracks past quotes as well as industry history to generate fast, reliable RFQs and more.

The company has also standardized on coolant, using the same Castrol Syntilo 9918 synthetic coolant for machining that it does for grinding. Mr. Godbold says the company could save money by using a lower-cost coolant, but it appreciates the consistent performance the advanced coolant offers. Comp Cams plans to install an 8,000-gallon central coolant system with a single main paper filter system to supply both the machining and grinding areas in the facility.

Originally, the prolonged camshaft-core delivery times had the company considering adding a “conventional” cell to produce the small batches that race teams required. Such cells typically include a saw to cut barstock to length; lathes to face the front and rear of the camshaft, add centers and groove the lobe layout; mills to machine details in the front and rear camshaft faces; and additional mills to machine the lobe profiles. Most of these operations required multiple time-consuming setups, too.

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Mighty magnets, alloys of a rare-earth element called neodymium, pack rich sound into a phone’s small speakers. Magnets also power the vibration motors that provide touch feedback on your device.

In 1926, Science News Letter described the promise of materials such as duralumin for safer dirigibles, which would carry large numbers of passengers into the air: “Of these sound materials, strong and light girders must be built. So light that a man can carry one of them in his hand and yet so strong that they will carry loads of thousands of pounds.” The rigid frame of the Hindenburg, for example, was made of duralumin.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly