Enabling Miniaturization with Micro Precision 3D Printing - short run plastic in

Author:gly Date: 2024-09-30

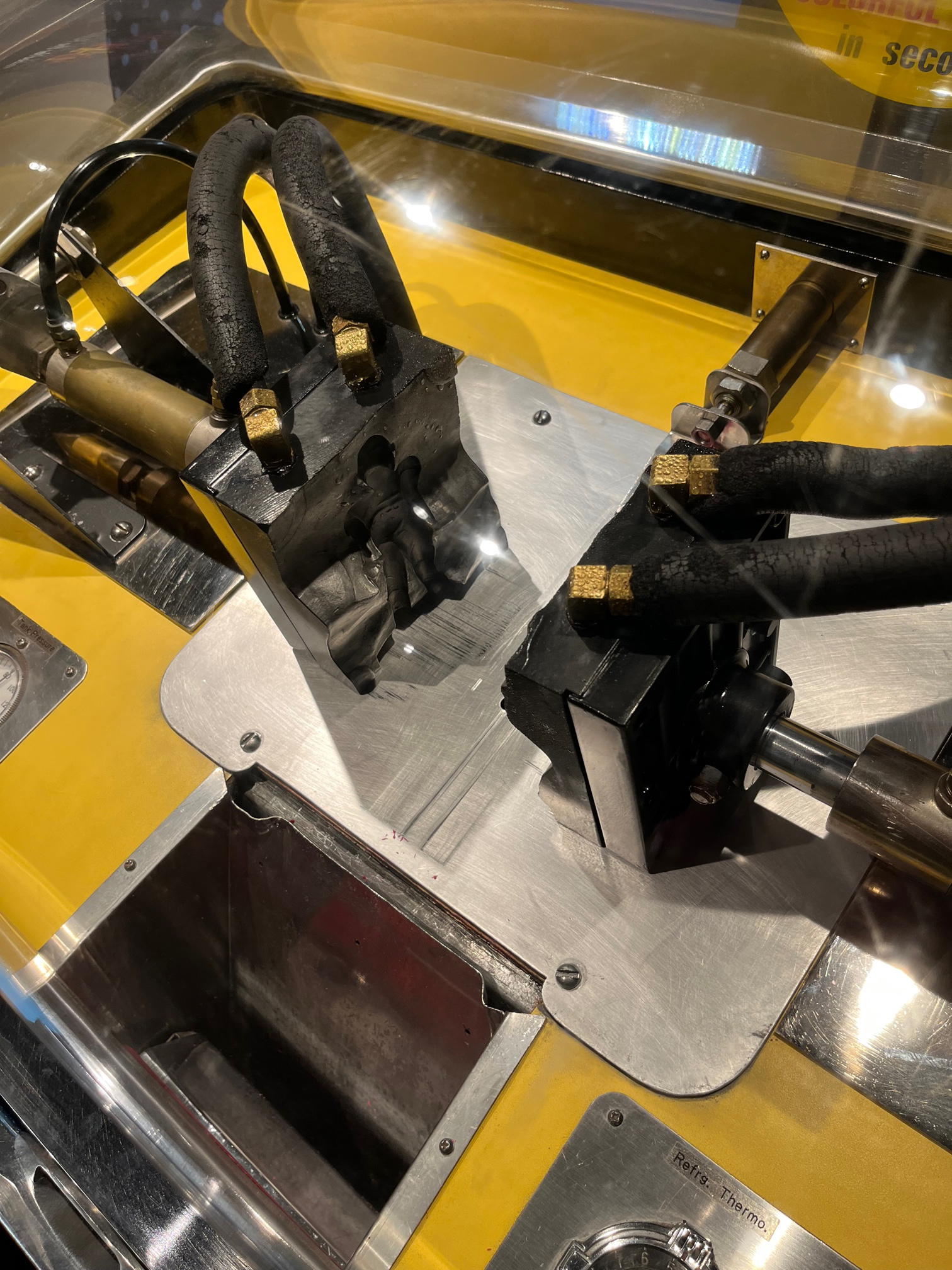

Here's how it works. First, insert your money into the machine. (Back in my day, each statue cost $1. The current price per figurine is $5. Thanks, inflation.) Next, two thick aluminum plates are pushed together, creating the mold. Polyethylene pellets, heated up to approximately 250°F, are then injected into the mold, while a blast of air works to hollow out the piece. Unnecessary plastic is removed through a drainage hole in the bottom of the mold. The statue is then cooled and hardened before the plates pull apart and the piece is pushed into the pick-up box.

The ALLROUNDER 720 E GOLDEN ELECTRIC features high-quality machine technology to ensure stable and reliable plastic parts production. This includes a toggle-type clamping unit and direct drives from ARBURG's subsidiary AMKmotion. With an electric mould height adjustment system, mould installation heights of up to 800 millimetres are possible. The drive components are optimised for a clamping force of 2,800 kN. The proven high-quality ARBURG plasticising with the "aXw Control ScrewPilot" ensures reproducible injection and excellent moulded part quality. Optimised mould venting with two-stage mould locking also plays a part in this. For convenient maintenance, the new electric ALLROUNDER has the same easily accessible control cabinet concept as the new hybrid machines. A lubrication unit and an optional pneumatic system are located on the operating side. The parts chute in the machine base has been widened, making it easily accessible.

Benefit from our expertise and lower the costs for your injection moulding production by optimising your energy requirement.

For reliable performance, a slimline design, and an unbeatable price, there is only one choice: the new ALLROUNDER 720 E GOLDEN ELECTRIC!

What happens when you combine a vending machine with plastic injection molding and add in a pinch of mid-century flair? You get a Mold-A-Rama machine. If you’re not a Midwesterner, then you might not know what I am talking about. But for those of us who grew up in Illinois, Minnesota, Michigan, or Wisconsin, Mold-A-Rama holds a special place in our nostalgic hearts. Every time I went to the Brookfield Zoo or the Field Museum of Natural History, I would drag my parents to the closest machine and beg them to buy me a tiny plastic statue. The real magic, however, was in watching the figurine being created right in front of our eyes in less than one minute. This became many kids’ first introduction to manufacturing.

The mid-century machines remain popular to this day. According to the current owner, one in 10 people who pass a machine buy a model, and the company uses about 640 55-pound bags of plastic pellets a year. Each Mold-A-Rama machine hold a gallon of hot liquid plastic and can produce up to 150 figures a day.

For reliable performance, a slimline design and an unbeatable price, there is only one choice: the new ALLROUNDER 720 E GOLDEN ELECTRIC!

ARBURG has optimised the design so that the new ALLROUNDER 720 E GOLDEN ELECTRIC, with a width of just 1,848 millimetres, has a significantly reduced installation area compared to other machines in its class. This has been achieved through features such as a new safety door with recessed handles. At the same time, the door opening has been widened to 1,400 millimetres, making the ejector area more accessible, for example. Due to its smaller installation area, the new ALLROUNDER fits into existing production grids and lines. This is of particular interest when old machine technology needs to be replaced. However, even for new production facilities that are being planned, every achievable space saving is a valuable resource. Thanks to the slim design, more machines can be set up in injection moulding production, resulting in an increased output per square metre.

The new electric machine can also be automated with linear Multilift robotic systems and six-axis robots from ARBURG. The exhibit is equipped with a Multilift V 30. At Fakuma 2024, the ALLROUNDER 720 E GOLDEN ELECTRIC with a clamping force of 2,800 kN and a size 800 injection unit will be producing PP razor covers by way of example. A 24-cavity mould from Hack will be used. The cycle time is around 11.5 seconds, with each moulded part weighing 1.2 grams. The 24 finished parts are then ejected in groups of four, clustered by cavity, into six boxes.

Alexis Gajewski has over 15 years of experience in the maintenance, reliability, operations, and manufacturing space. She joined Plant Services in 2008 and works to bring readers the news, insight, and information they need to make the right decisions for their plants. Alexis also authors “The Lighter Side of Manufacturing,” a blog that highlights the fun and innovative advances in the industrial sector.

The arburgXworld customer portal gives you access to a wide range of digital apps and features that make your daily work easier.

The new ALLROUNDER 720 E GOLDEN ELECTRIC with a clamping force of 2,800 kN extends the product range of the electric series of the same name upwards. Its main advantages in a nutshell? A slim design with a price to match. Following its world premiere at NPE in Orlando, US, and its European premiere at Plastpol in Kielce, Poland, ARBURG is now showing this machine for the first time at a trade fair in Germany at Fakuma 2024 (hall A3, stand 3101). It combines electrical precision, process stability and a small installation area with high component quality, low investment costs and short delivery times.

The Mold-A-Rama machine was invented by J.H. “Tike” Miller and debuted at the 1962 Seattle World’s Fair. The initial batch of models included a monorail, a Buddha, and a 3D sculpture of the Fair’s logo. The 1964 World’s Fair in New York City, however, made Mold-A-Rama a household name. It is said that as many as 150 machines were installed over the Fair’s two-year timeframe, and models included various dinosaurs, Disney characters, animals, and presidential busts. After being featured at the Montreal World’s Fair, Expo ’67, Mold-A-Rama machines became staples at museums, zoos, amusement parks, and anywhere that sold souvenirs.

The new electric machine is not limited to a specific product and is quickly available, which is particularly advantageous for short-term replacement purchases and capacity expansions. It is relevant for almost every industry and of particular interest for technical injection moulding. Other typical areas of application include dimensionally stable housings for electromobility, thick-walled closures for household goods, precision components for medical technology, and the construction and leisure industries. The ALLROUNDER 720 E GOLDEN ELECTRIC is equipped with the SELOGICA ND control system as standard. If required, additional options and functions such as core pulls and heating and cooling circuits can be easily integrated and programmed, enabling a wide range of plastic parts to be produced flexibly, efficiently and reliably.

If you’re looking to experience the magic of a Mold-A-Rama (or its cousin, the Mold-A-Matic) for yourself, here is a list of 10 locations where you can see these marvelous machines in action. If you happen to be in the Chicagoland area, take a trip to the Museum of Science and Industry and check out their latest exhibit, Mold-A-Rama: Molded for the Future.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly