Communities on troubled Java river mold future from plastic waste - mold and pla

Author:gly Date: 2024-09-30

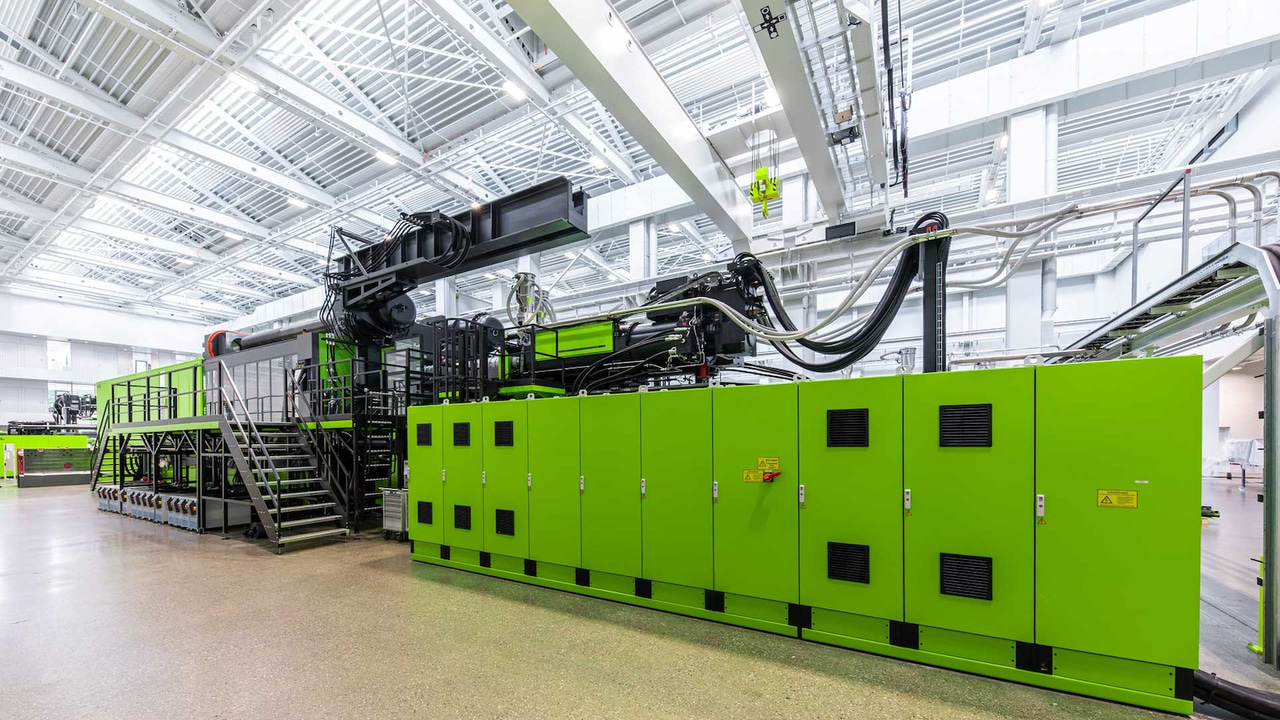

Until now, large plastic parts have often been manufactured using various processes other than injection molding, which have significant limitations. With the availability of an injection molding machine as large as the duo 5500 combi M in a technical center, extensive possibilities for part and technology development and sampling are now available. This offering reinforces Engel's role as an enabler of new technologies, allowing customers and partners to actively pursue developments in new dimensions and expand injection molding capabilities.

Dado rails are decorative mouldings installed horizontally along the wall, serving both aesthetic and practical purposes. They add a visual interest, dividing walls into distinct sections, and they provide a protective barrier against furniture scuffs and marks. MDF picture rails are installed nearer to the ceiling of the room, traditionally serving as a practical and aesthetic solution for hanging artwork and photographs but now more used for decorative appeal. With picture rails, you can effortlessly display and rearrange pictures without damaging walls. They offer versatility in decorating, allowing for easy adjustment of displayed items. Our MDF dado rails are supplied with two coats of primer to provide a smooth surface for painting.

Initially developed to mold large parts for the automotive sector, the press is now available for customer trials at the St. Valentin, Austria, technical center.

Engel reports that it has expanded its technical center in St. Valentin, Austria, with one of the largest injection molding machines from its standard portfolio — the duo 5500 combi M. With a clamping force of 55,000 kN and measuring 32 meters long, 13 meters wide, 6.8 meters high, and weighing 545 tonnes, it is by far the largest technical center machine in the world, according to Engel.

A dado rail is a horizontal moulding installed along the wall, typically positioned at chair height or slightly higher. It serves both decorative and practical purposes, dividing walls into distinct sections and providing protection against furniture scuffs and marks while enhancing the overall aesthetic of a room.

The height of a dado rail is typically determined by personal preference and the specific requirements of the room's design. However, a common recommendation is to install dado rails at a height of around 1/3 of the wall's total height. This positioning helps to visually divide the wall into upper and lower sections while providing a balanced and proportionate appearance to the room.

The company aims to use this machine to explore technologies and mold components in completely new dimensions in collaboration with its customers and partners. The extra-large mold space accommodates molds weighing up to 150 tonnes, with possible shot weights up to a massive 42 kg. The state-of-the-art machine was developed to meet the demands of the automotive industry and technical injection molding and is now available for customer trials.

The new Engel technical center facility covers all application areas for the automotive sector and technical injection molding.

Manufacturers of large, complex plastic parts and toolmakers can now test feasibility and implementation at an early project stage. This significantly shortens time to market and avoids costly subsequent errors by identifying and eliminating sources of error early on. Initial customer trials are scheduled to begin shortly.

Elevate the look of your walls with our range of dado and picture rails. Add a traditional feel to your home and shop the range to choose the right one for your space.

The duo 5500 combi M represents the latest technology in injection molding, said Engel in the announcement. It features two movable (combined and individually operable) horizontal injection units and a combi M injection unit. It is also equipped with two six-axis Engel easix articulated robots for flexible and efficient automation.

Stephen has been with PlasticsToday and its preceding publications Modern Plastics and Injection Molding since 1992, throughout this time based in the Asia Pacific region, including stints in Japan, Australia, and his current location Singapore. His current beat focuses on automotive. Stephen is an avid folding bicycle rider, often taking his bike on overseas business trips, and a proud dachshund owner.

The automotive industry increasingly uses larger plastic parts to reduce vehicle weight, improve fuel efficiency, and lower production costs. Plastics offer design flexibility, enhance corrosion resistance, and contribute to the longevity and safety of vehicles. They also allow for the integration of functional elements and reduce the number of individual parts needed. Engel’s new facility supports this trend by enabling the production of larger plastic components.

With the introduction of the duo 5500 combi M, Engel said it has reinforced its role as a leading hub for testing new technologies and collaborating closely with the industry to promote new injection molding possibilities. The machine allows for the testing and development of existing and new customer projects under real conditions and on neutral ground. This includes tool and material tests as well as the development of new manufacturing technologies.

To hang pictures on a picture rail, first, choose picture rail hooks or cords. Attach picture wire or cord to the back of the frame and position the hooks evenly along the rail based on frame width and desired arrangement. Hang your pictures by placing wire or cord onto hooks, making sure you use a level to ensure straight alignment. Finally, secure hooks onto the rail to create a versatile and hole-free display.

All digital assistance systems from Engel are integrated into the machine control, enabling energy-efficient, sustainable production while optimizing processes.

For PU applications, two Cannon systems are available — one for small-volume applications and another for high-volume output. A corresponding dosing unit allows for coloring the polyurethane.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly